Industrial Mobility

For decades Electric Industrial Mobility has been the way industries operate by providing sustainable and efficient transportation solutions. Embracing electric mobility not only reduces carbon emissions but also enhances operational efficiency, reliability, and cost-effectiveness.

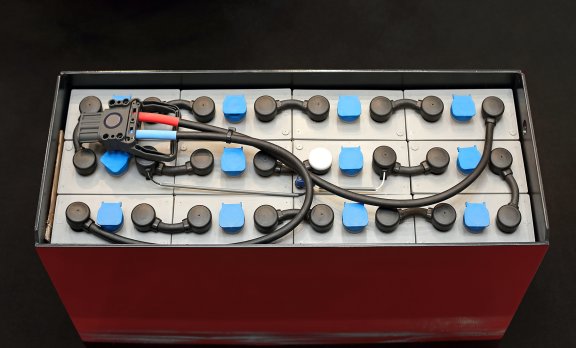

EnquiryMSS’ connectors, a modulable and reliable solution for your industrial lead-acid batteries

Our involvement in the supply of battery connectors to the industrial mobility sector stands as a cornerstone of our commitment to enabling electric industrial mobility.

By providing high-quality, durable, and efficient battery cable connectors, we ensure that the power needs of electric vehicles and machinery are met matching quality and reliability. Our connectors are designed to withstand the world rigors of industrial use, ensuring seamless integration with various battery modules / packs and enhancing the overall performance and safety of electric mobility solutions.

Related products

Components from battery production to battery maintenance

MSS International been a key player in this industry for the past 40 years, we manufacture millions of industrial battery products per year, stored and delivered through our logistic offices across the globe.

Our scope of supply includes:

- OPzV / OPzS Lead Battery Pillars

- Cable Connectors

- Take Off Leads

- Perfect Connectors

- Plastic Headed Bolts

- Brass Inserts

- Sealing Grommets

- Module Lids

Decades of product innovation at MSS International

MSS International has established itself as a key player in the supply of high-quality cable connectors for the past 40 years, consistently meeting the evolving demands in this sector. Our dedication to innovation and excellence has solidified our reputation as a reliable partner, providing essential components that enhance the performance and safety of advanced battery packs for main OEMs, as well as Tier 1 and 2.

01 / FAQs

What are the benefits of having lead-acid battery packs for forklift application?

Lead-acid batteries have long been a staple in forklift applications due to their cost-effectiveness, reliability, and ease of maintenance. These batteries provide consistent power output, making them suitable for the rigorous demands of industrial use. Typically, they are designed to endure deep discharge cycles while maintaining a stable energy supply, which is crucial for the uninterrupted operation of forklifts in various environments.

How often is a lead-acid battery serviced?

Regular maintenance for lead-acid batteries typically involves weekly inspections and monthly deep cleaning. This includes checking electrolyte levels, ensuring proper charging, and cleaning terminals to prevent corrosion. Such routine servicing extends the battery’s lifespan and ensures optimal performance.

Frequently Asked Questions about Industrial Mobility Components

02 / Downloads

03 / Certificates

ISO 9001 - MSS UK Global Source, Supply of Products including non-ferrous meta...

ISO 9001 - MSS Poland Manufacture and dispatch of components and assemblies for el...

ISO 45001 - MSS Poland Manufacture and dispatch of components and assemblies for el...

ISO 14001 - MSS Poland Manufacture and dispatch of components and assemblies for el...

IATF 16949 - MSS India Manufacture of electrical components....

9001 - 14001 - 45001 - MSS India Manufacture and Dispatch of Electrical Components...

Achilles Network Silver This is to certify that MSS Products Ltd are now fully regis...

RISQS 2024-25 This is to certify that MSS PRODUCTS LIMITED is now a verifi...

UVDB Silver+ MSS PRODUCTS LTD has successfully achieved the Achilles UVDB...