Powerful, Reliable Performance from Industry Leading Copper Busbars

MSS International is the manufacturer with the experience and global reach to offer efficiency, reliability, customisation, and delivery at scale for any project or product.

EnquiryBuild Better with MSS Products

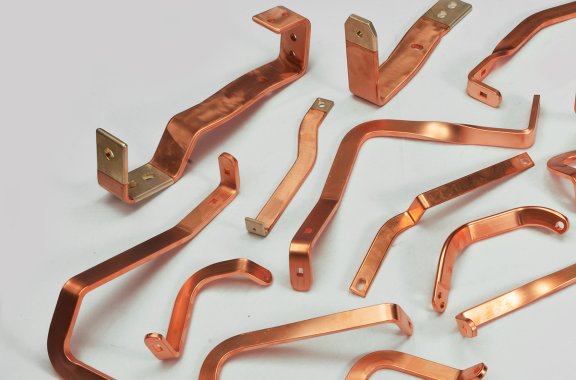

Premium Copper Materials for Busbars

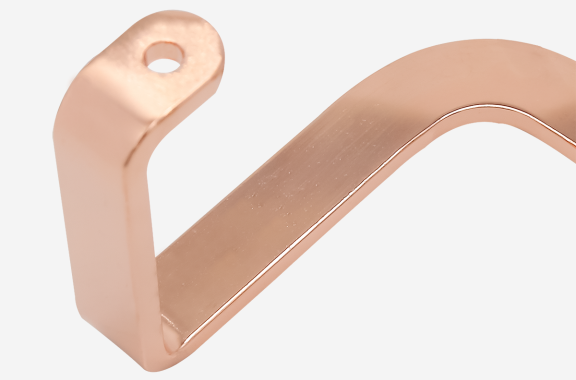

MSS International uses top-grade Copper ETP and OF grades to meet specific electrical requirements. Our solid copper bar stock is chosen for its excellent conductivity, ensuring reliable performance across applications, from switchboards to wind turbines.

Advanced Manufacturing Techniques

MSS employs processes like stamping, punching, and CNC bending, with an in-house engineering team providing tailored design solutions. Our flexible manufacturing allows for rapid prototyping and volume production, efficiently adapting to customer specifications.

Stringent Quality Control

Every copper busbar is thoroughly inspected in MSS’s state-of-the-art laboratory. With technology like CMM, dielectric tests, and go-no-go gauges, we ensure that every part meets the highest quality standards before shipment.

Use cases for our Busbar products

Innovative Busbar Features

Explore MSS Internationals’ technical mastery and cutting-edge technology.

- Copper ETP and OF grades

- CNC bending and punching

- In-house tool design

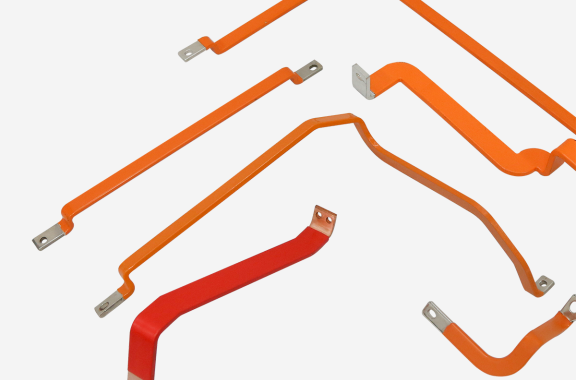

- Wide range of finishes

- Laser marking and labelling

- Custom insulation options

- Fastener fitting solutions

Global Leadership in Busbar Manufacturing

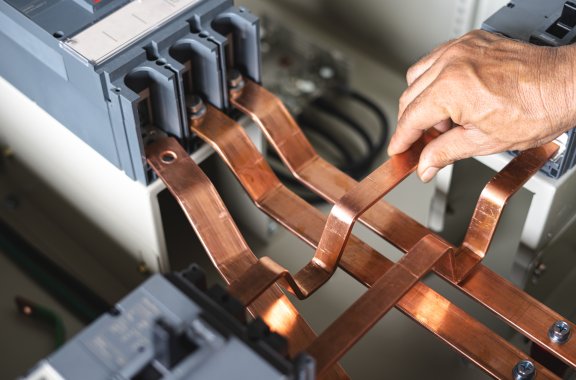

MSS International leads the industry in copper busbar design, consistently advancing with innovative techniques and tools. With vast experience and a global presence, we support customers through every stage—from prototype development to final product assembly—ensuring seamless integration and optimal performance.

End-to-End Service and Logistics

At MSS International, we don’t just manufacture; we offer a complete turnkey solution. Our dedicated logistics chain, including global warehouses, ensures efficient delivery to your door. We handle everything, from custom designs to duty-free shipments, so you can focus on your project with confidence.

Key Benefits:

- Custom Busbar Design: Every product is tailored to your unique specifications—no off-the-shelf solutions.

- Global Logistics Network: Reliable, fast delivery through established logistics channels.

- Duty-Free Delivery: MSS manages customs and compliance for a hassle-free experience.

01 / FAQs

Can busbars be customised?

Yes, MSS offers custom sizes, finishes, and configurations, ensuring optimal performance for your specific application.

What is a busbar?

A busbar is a metallic strip used to conduct electricity within a power distribution system, providing efficient current distribution across circuits.

What industries use copper busbars?

Copper busbars are used in sectors like renewable energy, power generation, battery storage, and electrical panels.

What materials are used in busbars?

MSS manufactures busbars primarily from high-grade copper (ETP and OF) and aluminium (1050 and 1060).

Why choose busbars over cables?

Busbars offer lower resistance, better current-carrying capacity, and more organised installations, making them more efficient and easier to maintain than cables.

How do you manufacture Busbars?

Busbars are metal strips or bars that conduct electricity and distribute it to various devices in a power system. Busbars are typically made of copper, aluminium, or brass, and can have various shapes and sizes depending on the application and integration in a system.

How fast is a busbar punching operation?

A busbar punching process is very fast, as it uses a hydraulic press or a CNC machine to create holes and cutouts in the busbars according to the design specifications. The punching speed depends on the material, thickness, and shape of the busbar, but it can range from 2 to 15 seconds per hole.

Frequently asked questions about Busbars

We have more information regarding this topic in our resources section.

All Resources02 / Downloads