Laminated Copper Flexible Connectors – Trusted, Efficient, and Customisable Solutions

MSS International specialises in laminated copper flexible connectors that offer enhanced conductivity, durability, and adaptability across critical applications.

EnquiryBuild Better with MSS International

High-Grade Copper for Superior Conductivity and Efficiency

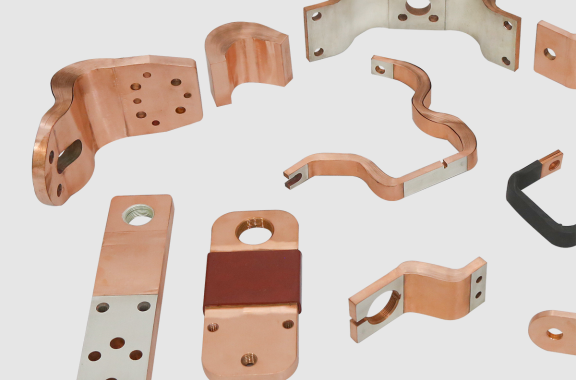

Crafted from premium-grade ETP copper foils, our laminated copper flexible connectors ensure low electrical resistance and high conductivity, making them ideal for applications where efficient energy transfer is critical. Each copper foil layer is consolidated under controlled heat and pressure, forming a solid conductive path that handles high currents with minimal heat buildup, providing a robust solution for industrial power needs and electrical infrastructure.

Advanced, Customizable Production for Precision and Quality

MSS integrates advanced semi-automated processes, including precision welding, foil cutting, and machining. This enables us to produce connectors that meet unique specifications, offering a high degree of customization in plating and finishing. Available options include tin, silver, and nickel plating to maximise contact efficiency, corrosion resistance, and performance in demanding environments. Our production flexibility allows each connector to be precisely adapted to client requirements in electric vehicles, switchgear, transformers, and more.

Stringent Testing for Unmatched Reliability

Our laminated connectors undergo rigorous quality testing to meet high standards for durability and safety. From insulation integrity checks to plating thickness verification, every detail is verified to ensure performance under extreme conditions. Our connectors use UL94 V0-rated insulation withstanding temperatures up to 150°C, making them suitable for high-stress environments across industries such as renewable energy, power distribution, and transportation.

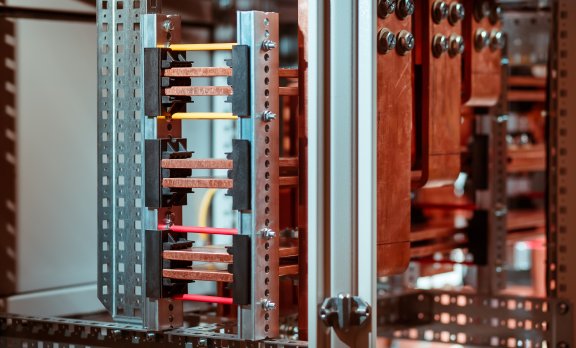

Applications for Laminated Flexibles

Innovative Features of MSS Laminated Flexibles

MSS's laminated copper connectors combine technical precision with innovative design, providing industry-leading performance in the most challenging applications. Key features include:

- Premium Copper Foil Construction for Enhanced Conductivity

Each connector is built from high-quality ETP copper foil, with thicknesses ranging from 0.03 mm to 0.5 mm. This foil-based design offers superior conductivity and lower resistance than traditional solid conductors, optimising energy efficiency and reducing heat buildup for high-demand applications like power generation and industrial manufacturing.

- Precision Machining for Custom Fit and Performance

Our lamination process ensures a consolidated, busbar-like connection that supports additional machining for specialised contacts. This allows the integration of fasteners, plated contacts, and other components, ensuring that each connector can meet specific operational requirements without compromising structural integrity.

- Advanced Plating Options for Enhanced Contact and Corrosion Resistance

MSS offers extensive plating solutions, including tin, silver, and nickel, with customizable thicknesses from 2 to over 100 microns. These options optimise conductivity at contact points and protect against corrosion, extending the lifespan and reliability of connectors in applications ranging from renewable energy systems to heavy machinery.

- Customizable Insulation and Compliance for Safety in High-Voltage Applications

Our UL94 V0 insulation is available in both automotive-grade RAL2003 orange and standard black/grey finishes. With dielectric strengths exceeding 20kV/mm, these connectors are designed for high-voltage applications, ensuring safety and compliance across critical industries, including industrial mobility and solar energy.

Global Leadership in Laminated Flexible Manufacturing

MSS International leads the industry in laminated flexible technology with a global production capacity and comprehensive support, from design to delivery. Our dedicated logistics team ensures efficient worldwide delivery, giving clients a full-service solution tailored to their project’s specifications.

End-to-End Services and Logistics

MSS handles every stage of the process, from custom design and prototype development to high-volume production and duty-free shipping. Our global logistics network ensures fast, reliable delivery, enabling clients to focus on their project goals.

01 / FAQs

Are these connectors suitable for high-temperature applications?

Yes, MSS’s connectors come with UL94 V0-rated insulation capable of withstanding temperatures up to 150°C, making them suitable for high-temperature environments across industries, including renewable energy and power distribution.

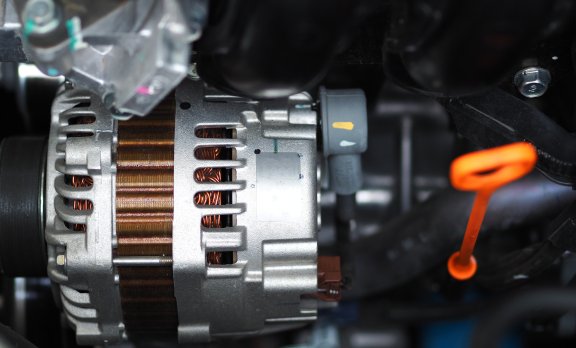

Can laminated copper connectors improve energy efficiency?

Yes, laminated copper connectors are designed to reduce electrical resistance and minimise energy loss, improving overall system efficiency in applications like transformers, generators, and electric vehicles.

How solid is the consolidated area?

After lamination, the consolidated area is as robust as a standard busbar, providing a strong, durable connection. Additional machining can be applied to accommodate specialised contact points, fasteners, and plating for enhanced performance.

What is the process of busbar flexible lamination?

Busbar flexible lamination involves cutting high-quality copper foil into strips, stacking and bonding them under heat and pressure to create a solid, durable connection. Finished units can be customised with plating, insulation, and complex machining for specific applications.

What plating options are available for laminated connectors?

MSS offers tin, silver, and nickel plating options, with customisable thicknesses ranging from 2 to over 100 microns. These enhance conductivity at contact points and provide corrosion resistance, crucial for durability in various environments.