Data centre power distribution management has become one of the most critical engineering challenges of our digital age. As artificial intelligence workloads push power densities from traditional 4-6kW per rack to demanding 20-60kW configurations, the electrical infrastructure supporting these facilities requires unprecedented precision, reliability, and efficiency.

The stark reality facing data centre operators today is that data centre power consumption continues to surge while tolerance for downtime approaches zero. Microsoft's $500 million data center in Chicago required 2,177 tonnes of copper for construction, equivalent to 27 tonnes per megawatt of applied power. This figure isn't just impressive; it's indicative of copper's fundamental role in enabling the digital infrastructure that powers our economy.

At MSS International, our 50+ years of precision engineering for electrical transmission and distribution gives us unique insight into these challenges. Through our global manufacturing operations and specialised G Corner division, we've seen firsthand how copper data centre applications must evolve to meet the relentless demands of modern computing infrastructure.

Here's what we'll cover:

- Why traditional electrical infrastructure approaches fail under modern AI and cloud computing loads

- How copper electrical infrastructure delivers the reliability and efficiency data centres demand

- Critical applications where data centre copper components make or break operational success

- The economics of copper vs. alternatives in high-stakes data centre environments

- Future-proofing strategies for evolving data centre power distribution requirements

Understanding these fundamentals is essential for anyone responsible for data centre infrastructure that must deliver 99.995% availability while managing ever-increasing power densities.

The infrastructure challenge: when traditional systems hit their limits

The AI power crisis

The computational demands of artificial intelligence have fundamentally altered data centre infrastructure requirements. AI requires 10 times the resource requirements of traditional cloud computing, according to Macquarie Data Centres. This isn't just about processing power but translates directly into electrical infrastructure that must handle currents and power densities far beyond what legacy systems were designed to support.

Traditional data centre racks consuming 4-6kW are being replaced by AI-ready configurations demanding 40-60kW per rack. For perspective, this means a single modern AI rack consumes as much power as 15-20 traditional server configurations. The electrical distribution systems (busbars, connectors, cooling infrastructure) must scale accordingly without compromising reliability.

The reliability imperative

Data centre downtime costs range from $137 per minute to over $1 million per hour, making infrastructure reliability a business-critical imperative. Tier 4 facilities require 99.995% availability, allowing for just 0.4 hours of downtime annually over five years. Achieving this standard demands electrical components that perform flawlessly under extreme conditions.

The challenge isn't just handling higher loads but doing so while maintaining the precise voltage regulation, thermal management, and fault protection that prevent cascading failures. When a single component failure can take down hundreds of servers and impact thousands of end users, there's no room for compromise in material selection or manufacturing precision.

Supply chain complexity at scale

The sheer scale of modern data centre construction amplifies every supply chain challenge. North American data center infrastructure is projected to grow from $33 billion in 2020 to $185 billion by 2040. This growth demands consistent supply of high-quality electrical components manufactured to exacting specifications.

Standard industrial components often lack the precision and reliability required for mission-critical data centre applications. Custom engineering and manufacturing become essential to bridge the gap between what's available off-the-shelf and what's needed for 24/7 operation at high power densities.

Why copper dominates data centre electrical infrastructure

Unmatched electrical performance under extreme conditions

Copper electrical infrastructure delivers performance advantages that become critical at high power densities. Copper has nearly 60% higher electrical conductivity than cost-competitive alternatives, directly translating to lower I²R losses and reduced heat generation. At 20kW+ per rack, these efficiency gains aren't just beneficial; they're essential for maintaining system stability.

MSS International specialises in Electrolytic Tough Pitch (ETP) copper, recognised globally for its superior conductivity and reliability. Our precision manufacturing processes ensure optimal grain structure and purity, maximising conductivity while providing the mechanical properties required for demanding data centre applications.

Thermal management that scales

Data centre power consumption at modern levels generates enormous amounts of heat that must be efficiently removed to prevent equipment damage and maintain performance. Copper's thermal conductivity helps build efficient heat exchangers, which are vital for cooling in data centres. This thermal performance becomes particularly critical in high-density busbar systems where multiple conductors carry substantial currents in close proximity.

The ability to conduct heat away from connection points and distribute it across larger conductor surfaces prevents hot spots that could lead to component failure or fire hazards. This becomes increasingly important as power densities continue rising with AI workloads.

Long-term reliability in harsh environments

Data centres operate continuously in environments with temperature fluctuations, humidity variations, and electromagnetic interference. Copper's natural corrosion resistance and stable electrical properties ensure consistent performance over the 20+ year lifespan typical of data centre infrastructure investments.

Unlike alternatives that may degrade or develop high-resistance connections over time, properly manufactured copper components maintain their electrical and thermal characteristics throughout their service life. This reliability is essential for facilities that cannot tolerate performance degradation or unexpected maintenance requirements.

Critical applications: where copper makes the difference

High-current power distribution systems

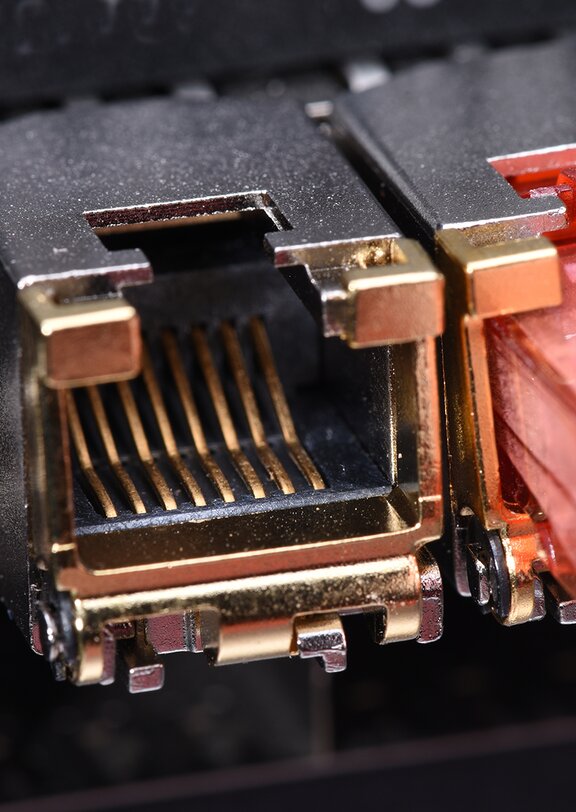

Data centre power distribution systems represent the most demanding application for copper in these facilities. Power distribution systems claim 75% of the total copper content in data centres. MSS International's custom DC busbar systems are engineered to handle the substantial electrical loads required by modern data centres while maintaining efficiency and safety standards.

Primary distribution busbars Our ETP copper busbars carry power from utility transformers and backup generators to distribution panels throughout the facility. Advanced heat and electrical resistance simulations optimise conductor geometry and connection design, ensuring minimal voltage drop and heat generation even at maximum load conditions.

Secondary distribution networks From distribution panels to individual server racks, copper conductors must maintain voltage regulation while accommodating varying load conditions. Our flexible and solid conductor configurations adapt to different installation requirements while maintaining consistent electrical performance.

Grounding and bonding systems Comprehensive grounding systems protect both equipment and personnel from electrical faults. MSS International manufactures precision grounding conductors and connection hardware that ensure reliable fault current paths and electromagnetic compatibility throughout the facility.

Power quality and protection components

Switchgear and circuit breaker components Our precision-engineered contact assemblies and disconnector systems ensure reliable circuit protection and safe isolation during maintenance. These data centre copper components undergo rigorous testing including torque verification, voltage endurance checks, and thermal cycling to validate performance under real-world conditions.

UPS and power conditioning integration Uninterruptible power systems require high-quality electrical connections to maintain power quality during utility disturbances and generator transfers. Our custom assemblies provide the reliable connections essential for maintaining the clean power that sensitive IT equipment requires.

Thermal management infrastructure

Cooling system components In HVAC systems, copper pipes, and coils are essential for heat exchange, facilitating effective temperature control. MSS International's copper components integrate with chilled water systems, direct expansion cooling, and emerging liquid cooling technologies.

Heat sink and thermal interface applications As server power densities increase, effective thermal interfaces become critical for removing heat from processors and power components. Our precision machining capabilities produce custom heat sinks and thermal management components optimised for specific cooling requirements.

The economics: why copper delivers superior value

Efficiency translates to operating savings

Lower electrical resistance directly reduces operating costs through decreased energy losses. At the power levels typical in modern data centres, even small efficiency improvements generate substantial savings over the facility's operational lifetime.

Consider a 100MW data centre operating continuously: a 1% efficiency improvement saves 8,760 MWh annually. At typical commercial electricity rates, this represents hundreds of thousands of dollars in annual savings far exceeding any premium for high-quality copper components.

Reliability prevents costly downtime

The cost of data centre downtime far exceeds the cost of premium electrical components. High-quality copper data centre infrastructure reduces the risk of failures that could result in service outages costing millions of dollars per incident.

MSS International's comprehensive quality assurance processes, including ISO 9001 and IATF 16949 certifications, ensure consistent component performance that supports facility uptime requirements. Our advanced simulation tools and rigorous testing protocols validate component performance before installation, reducing the risk of field failures.

Lifecycle cost advantages

While copper components may require higher initial investment than alternatives, their superior performance and longevity deliver better lifecycle economics. Copper's resistance to corrosion and degradation maintains performance over decades of service, while alternatives may require replacement or maintenance that increases total cost of ownership.

Additionally, copper's recyclability means components retain value at end of life. Copper parts can be made from more than 95% recycled material without performance loss, supporting both economic and environmental objectives.

Future-proofing data centre infrastructure

Adapting to emerging technologies

The data centre industry continues evolving rapidly, with edge computing, 5G networks, and advancing AI applications driving new infrastructure requirements. Data centre copper components must adapt to higher power densities, different cooling approaches, and more sophisticated power management systems.

MSS International's research and development capabilities ensure our solutions can accommodate emerging technologies while maintaining the reliability and efficiency that data centres require. Our custom engineering approach enables rapid adaptation to new requirements without compromising performance or delivery schedules.

Scalability and modularity

Modern data centre design emphasises incremental expansion and flexible configuration. Our modular busbar systems and standardised connection interfaces enable operators to expand capacity efficiently while maintaining consistent performance standards throughout the facility.

This scalability becomes particularly important as operators balance infrastructure investment with uncertain demand growth. The ability to expand electrical capacity incrementally reduces capital risk while ensuring adequate power availability for growth opportunities.

Sustainability and environmental responsibility

Environmental considerations increasingly influence data centre infrastructure decisions. Copper's sustainability advantages (high recycled content, recyclability, and energy efficiency) align with operators' environmental goals while supporting operational performance.

MSS International's commitment to sustainable manufacturing includes 25% renewable energy at our facilities, 90% recycled lead content, and 100% recycled brass in our supply chain. These practices reduce the environmental impact of our products while maintaining the performance characteristics that data centres require.

MSS International: precision engineering for data centre excellence

Comprehensive manufacturing capabilities

With manufacturing facilities in India and Poland, plus global sales and service operations spanning the UK (Global HQ), USA, France, Germany, Italy, Spain, Chile, Japan, Thailand, Mexico, and Australia, MSS International delivers the global reach and local responsiveness that data centre projects require. Our annual output exceeds 1 million high-precision components, ensuring consistent supply for projects of any scale.

Strategic presence in key data centre markets

MSS International maintains a strong presence in the world's most critical data centre markets. Our established operations across the European Union and United States position us to support the rapid expansion of data centre infrastructure in these regions. With local sales and service teams in the USA, France, Germany, Italy, and Spain, we provide the responsive support that mission-critical projects demand. This regional presence enables us to navigate local regulations, understand market-specific requirements, and deliver components that meet regional standards while maintaining our global quality benchmarks. As data centre construction accelerates in both North America and Europe, driven by AI adoption and cloud computing growth, our strategic footprint ensures we can support projects from initial design through long-term operation.

Custom engineering excellence

Our in-house design capabilities enable development of bespoke solutions tailored to specific data centre requirements. Advanced simulation tools for thermal and electrical performance optimise designs before manufacturing, ensuring components meet exact specifications while minimising development time.

From individual components to complete assemblies, we provide end-to-end support that simplifies procurement and integration for data centre operators and contractors.

Quality assurance that counts

All MSS International products are backed by comprehensive quality management systems including ISO 9001 and IATF 16949 certifications. Our testing protocols include electrical performance verification, thermal cycling, torque testing, and dimensional inspection to ensure every component meets demanding data centre standards.

Advanced heat and electrical resistance simulations validate design performance before production, while ongoing process monitoring ensures consistent quality throughout manufacturing.

The path forward: copper's continued critical role

Market growth driving demand

Data centre construction continues accelerating globally, with particularly strong growth in AI-ready facilities. Between 2018 and 2023, the number of hyperscale data centres worldwide doubled from 448 to 992, with no signs of slowing growth.

This expansion drives sustained demand for high-quality copper electrical infrastructure that can reliably handle the power densities and performance requirements of next-generation data centres.

Innovation opportunities

As data centre requirements continue evolving, opportunities for innovation in data centre power distribution management expand. MSS International remains at the forefront of these developments through:

- Advanced copper alloy development for specific applications

- Improved manufacturing processes that enhance performance and reduce costs

- Enhanced component integration that simplifies installation and improves reliability

- Sustainable production methods that reduce environmental impact

Strategic partnership advantages

The complexity of modern data centre infrastructure makes strategic partnerships essential. Working with experienced manufacturers who understand both the technical requirements and commercial pressures of data centre development provides significant advantages in project execution and long-term facility performance.

MSS International's combination of technical expertise, manufacturing capacity, and global reach makes us an ideal partner for data centre infrastructure projects that cannot accept compromise in performance or reliability.

Conclusion: building the foundation for digital infrastructure

Data centre power distribution systems form the critical foundation that enables our digital economy. From cloud computing platforms to artificial intelligence applications, these facilities depend on electrical infrastructure that performs flawlessly under extreme conditions while adapting to ever-increasing demands.

Copper data centre applications provide the performance, reliability, and efficiency that these critical systems require. Through superior electrical conductivity, thermal management capabilities, and long-term durability, copper components enable data centre operators to achieve the uptime and performance standards their customers demand.

At MSS International, we're committed to advancing this critical infrastructure through precision engineering, innovative manufacturing, and unwavering quality standards. Our comprehensive capabilities (from raw material sourcing through final assembly) ensure data centre operators worldwide can rely on our solutions to meet both current requirements and future challenges.

The future of digital infrastructure depends on electrical systems that deliver uncompromising performance. With data centre power consumption continuing to grow and reliability requirements becoming more stringent, copper's unique combination of properties makes it indispensable for next-generation data centre infrastructure.

Ready to future-proof your data centre infrastructure with precision-engineered copper solutions? Contact MSS International today to discuss how our comprehensive manufacturing capabilities and custom engineering expertise can optimise your facility's power, performance, and reliability.