Manufacturing electrical components for modern infrastructure requires energy-intensive processes. MSS International demonstrates that precision manufacturing and environmental responsibility can work together. Through systematic carbon reduction initiatives spanning renewable energy, smart technologies, and operational efficiency, we're delivering measurable emissions cuts while maintaining the precision and reliability our customers expect.

The challenge facing electrical component manufacturers is stark: meet growing demand for critical infrastructure components while dramatically reducing carbon intensity. Traditional manufacturing approaches in sectors like switchgear, busbars, and power distribution systems typically involve high-energy machining, pressing, and assembly processes. The industry needs partners who can deliver both technical excellence and verified environmental performance. MSS International provides exactly that combination, with concrete emissions reductions that help customers meet their own sustainability targets without compromising on quality.

Here's what we'll cover in this article:

- How strategic renewable energy deployment cuts operational emissions while strengthening manufacturing resilience

- Smart technologies that eliminate travel-related emissions without sacrificing customer collaboration

- Systematic efficiency measures across machining, pressing, and assembly operations that reduce energy intensity

- The business case for carbon reduction in electrical component manufacturing

- MSS's roadmap to carbon neutrality by 2045 and what it means for supply chain partners

Understanding these operational realities demonstrates how manufacturers can achieve both environmental and business objectives simultaneously.

Energy-intensive manufacturing meets renewable power

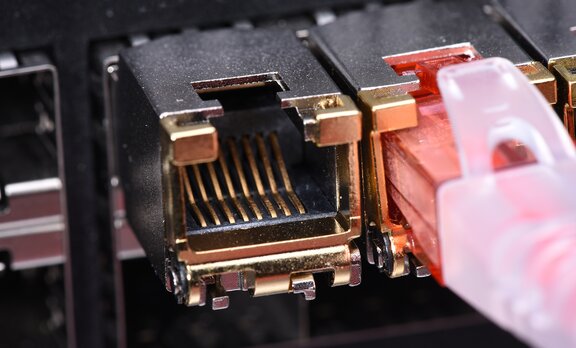

Producing electrical components like busbars, switchgear assemblies, and precision connectors requires significant electricity for CNC machining, pressing operations, and surface treatment processes. The carbon intensity of these manufacturing steps directly correlates to the grid electricity sources used. By systematically transitioning to renewable energy, MSS International has achieved measurable emissions reductions while improving long-term energy cost stability.

The challenge: High-energy manufacturing processes

Electrical component manufacturing is inherently energy-intensive. Precision CNC machining of copper busbars demands continuous high-power spindle operation. Hot pressing of complex shapes requires sustained heat and pressure. Surface treatment and electroplating processes run energy-demanding pumps, heaters, and treatment systems around the clock. These operational realities mean that the carbon intensity of electricity supply directly impacts the environmental footprint of every component produced.

For customers in renewable energy, electric vehicles, or green infrastructure projects, the embedded carbon in their electrical components becomes a critical consideration. They need manufacturing partners who can demonstrate real emissions reductions, not just offsetting strategies or vague commitments.

MSS's solution: Large-scale solar deployment with measurable results

MSS International has installed 453 kWp of solar capacity across our facilities, generating clean electricity directly at the point of consumption. This isn't symbolic green marketing, it's industrial-scale renewable energy deployment that measurably reduces the carbon intensity of every busbar, connector, and assembly we produce.

The results are quantified and verified: our solar installations reduce emissions by 623 tonnes annually, equivalent to the impact of planting 28,622 mature trees and avoiding 299 tonnes of coal consumption. This renewable energy powers the precision machining centers that produce copper busbars for electrical distribution systems, reducing the carbon footprint embedded in components used across power generation, transmission, and distribution infrastructure.

Looking ahead, our 2026-27 expansion plan targets 2.5MW of additional renewable capacity across all five MSS plants, projected to eliminate 2,500 tonnes of carbon emissions annually. This significant scale-up will generate an estimated 3.8 million kWh of clean electricity yearly, further reducing the environmental impact of electrical component production while providing energy cost stability.

Smart technology eliminating travel emissions

The traditional model of manufacturing quality control and customer collaboration involved extensive travel for inspections, approvals, and problem-solving. In electrical component manufacturing, where precision tolerances and quality verification are critical, this meant frequent site visits, international travel for customer approvals, and cross-site technical consultations. MSS International has systematically eliminated these emissions through advanced technology solutions that maintain (and often improve) collaboration quality.

RealWear Technology: Remote Inspection Without Compromise

MSS has deployed RealWear smart wearable devices that enable hands-free, voice-operated remote inspections. Engineers can share live video from CNC machining operations, busbar assembly lines, or quality control stations, allowing real-time customer approvals and technical collaboration without travel.

This technology has eliminated numerous business trips for product development and inspection processes, delivering GHG emission reductions while accelerating decision-making. Customers can observe precision machining operations, verify surface treatments, and approve assembly procedures remotely, maintaining the technical rigor required for electrical components while cutting travel-related emissions.

Virtual factory tours and digital collaboration

Building on remote inspection capabilities, MSS launched virtual factory tours that provide comprehensive facility access without physical visits. Customers can observe our pressing operations, CNC capabilities, and quality control processes through secure video collaboration, removing routine site visits while maintaining transparency about manufacturing capabilities.

These digital solutions particularly benefit international customers sourcing electrical components, eliminating the carbon cost of routine supplier audits and technical reviews while providing better documentation and repeatability than traditional site visits.

Systematic efficiency across manufacturing operations

Beyond renewable energy, MSS International has implemented comprehensive efficiency measures across our electrical component manufacturing operations. These initiatives target the specific energy demands of machining, pressing, surface treatment, and assembly processes, delivering both environmental and operational benefits.

LED lighting and natural daylight integration

Converting manufacturing areas to LED lighting while incorporating transparent roofing to maximize natural daylight has reduced electricity consumption by approximately 10%, cutting annual CO₂ emissions by over 213,000 kg. This seemingly simple change delivers measurable impacts because electrical component manufacturing requires consistent, high-quality illumination for precision work.

The improved lighting quality also enhances visual inspection of machined surfaces, busbar connections, and assembly details, supporting quality objectives while reducing energy consumption.

Smart air and process management

Manufacturing electrical components requires compressed air for pneumatic tooling, CNC coolant systems, and cleaning operations. MSS has installed air flow controller valves across all CNC and VMC machines to reduce compressed air pressure from 6 bar to 3 bar where technically feasible, enabling operation with lower-capacity compressors.

Combined with regular leak detection audits and systematic replacement of connectors, pipes, and cylinder seals, these measures reduce the energy intensity of air compression (a significant electricity consumer in manufacturing operations).

High-volume, low-speed (HVLS) fans with variable frequency drives provide efficient air circulation across large production areas, reducing air-conditioning demand while maintaining optimal conditions for precision manufacturing and employee comfort.

Process equipment optimisation

VFD drives on pressing machines and stamping equipment optimise power usage by matching motor speed to operational requirements rather than running at constant high power. Timer installations on vibratory equipment enable automatic shutdown after cycle completion, preventing unnecessary energy consumption during production gaps.

These incremental improvements accumulate to meaningful efficiency gains across the electrical component production process, reducing both operational costs and emissions.

Water: Zero discharge, maximum efficiency

Water management in electrical component manufacturing extends beyond consumption to encompass treatment of process water from machining coolants, surface treatment operations, and facility maintenance. MSS International operates a zero liquid discharge (ZLD) system that treats, recovers, and reuses water throughout our operations.

Our integrated water treatment approach processes 26,000 litres daily through effluent and sewage treatment plants, with secondary RO treatment recovering an additional 3,000 litres for reuse in surface treatment processes. The ZLD evaporator plant ensures zero discharge to the environment, supporting both water conservation and environmental protection.

This closed-loop water management reduces freshwater demand while ensuring that machining and surface treatment operations maintain consistent quality standards. For customers focused on supply chain sustainability, this verified zero-discharge approach provides concrete evidence of environmental responsibility.

Materials and circular manufacturing practices

Producing electrical components generates various waste streams: metal offcuts from machining operations, packaging materials from raw material deliveries, and end-of-life components requiring responsible disposal. MSS International has implemented systematic circular practices that minimize waste while supporting resource efficiency.

Wood packaging reuse program

Since 2019, MSS has systematically reused wooden packaging boxes from imported raw materials for local shipping purposes, saving approximately 4 tonnes of wood monthly (over 200 tonnes to date). This straightforward circular practice reduces waste disposal costs while eliminating demand for new packaging materials.

The transition from master wooden cartons to corrugated boxes for general packaging further reduces weight, improves recyclability, and supports more efficient logistics while maintaining component protection standards.

Recycled material integration

MSS has integrated recycled lead from terminal pillars into production processes since 2017, demonstrating practical circular economy principles in electrical component manufacturing. This reduces raw material demand while ensuring consistent material quality for demanding applications.

Our transition to recycled paper for office stationery contributes additional resource conservation: each tonne of recycled paper saves 17 trees, 31,800 litres of water, and 2,100 litres of oil compared to virgin paper production.

The business case for carbon reduction in manufacturing

For MSS International's customers in electrical infrastructure, renewable energy, and industrial applications, supplier carbon performance increasingly impacts procurement decisions. Demonstrating verified emissions reductions through renewable energy, efficiency measures, and circular practices provides competitive advantages while supporting customer sustainability objectives.

Our EcoVadis Gold rating (placing MSS in the top 5% globally for environmental performance) validates these efforts through independent assessment. This certification provides customers with credible evidence of supply chain sustainability, supporting their own environmental reporting and target achievement.

Behind these achievements sits a dedicated ESG team working systematically on year-on-year improvements across all environmental, social, and governance metrics. This team reports directly to board management level, ensuring carbon reduction targets, resource efficiency initiatives, and circular economy programmes receive strategic oversight and accountability. The traceability of our continuous improvement process isn't just documented for compliance, it's embedded in our operational culture, with measurable targets, regular progress reviews, and transparent reporting that demonstrates the seriousness of our commitment to sustainable manufacturing.

The operational efficiency gains from energy reduction and waste minimisation deliver direct cost benefits that strengthen our competitive position while supporting continued investment in environmental improvements. Renewable energy provides long-term electricity cost stability, efficiency measures reduce operational expenses, and circular practices minimise waste disposal costs.

Roadmap to carbon neutrality by 2045

MSS International has committed to achieving complete carbon neutrality by 2045 through systematic expansion of renewable energy, continued efficiency improvements, and strategic technology deployment. This target encompasses Scope 1, 2, and 3 emissions across our global operations.

The 2026-27 renewable energy expansion represents a critical milestone, with 2.5MW of additional solar capacity projected to eliminate 2,500 tonnes of annual emissions. Combined with planned efficiency measures, electric vehicle transitions, and continued circular practices, this positions MSS to achieve substantial emissions reductions well before the 2045 target.

For supply chain partners, this roadmap provides visibility into long-term environmental performance improvements and supports their own carbon reduction planning. As electrical infrastructure increasingly supports renewable energy deployment and electrification initiatives, partnering with manufacturers demonstrating verified carbon reduction creates strategic alignment with global decarbonization trends.

Manufacturing precision with environmental responsibility

The electrical component manufacturing industry faces mounting pressure to reduce environmental impact while maintaining the precision, reliability, and performance that critical infrastructure demands. MSS International demonstrates that these objectives are not conflicting but complementary, with systematic environmental improvements supporting both operational efficiency and customer value creation.

Our comprehensive approach, spanning renewable energy deployment, smart technology adoption, systematic efficiency measures, and circular practices, delivers measurable carbon reduction while strengthening manufacturing capabilities. The 213,000 kg of CO₂ reduced since 2019 represents concrete environmental progress, while our operational improvements support continued growth in serving electrical infrastructure markets.

For customers developing renewable energy systems, electric vehicle infrastructure, or grid modernization projects, partnering with MSS International means accessing both technical expertise and verified environmental performance. Our carbon reduction journey supports your sustainability objectives while delivering the precision electrical components that enable the clean energy transition.

Ready to reduce your supply chain carbon footprint without compromising on component quality? Contact MSS International today to explore how our manufacturing capabilities and environmental leadership can support your electrical infrastructure projects while advancing your sustainability goals.

Back to resources