Manufacturing bottlenecks for critical electrical components are severely hindering green hydrogen project scale-up, demanding proven, specialised partners to bridge the gap between ambition and operational reality.

The promise of green hydrogen in the energy transition is undeniable, offering a pathway to decarbonize challenging sectors. Yet, while investment announcements soar, turning plans into producing assets faces significant hurdles. The stark reality is that while global investment announcements surged to $680 billion by mid-2024, only about 11% of this ($75 billion across 434 projects) had reached a Final Investment Decision (FID), often due to hardware and supply chain challenges.

Successfully scaling requires consistently delivering high-quality, reliable components, particularly for the vital electrical and power distribution infrastructure underpinning green hydrogen systems. This is where proven engineering depth and focused manufacturing expertise become indispensable. MSS International, strengthened by the specialised high-power DC capabilities of its G Corner division, provides a concrete pathway, offering tangible solutions centered on the electrical heart of these projects.

Here’s what we’ll cover in this article:

- How precision manufacturing ensures reliability for critical BoP electrical and supporting components.

- G Corner's specialised role in mastering high-power DC systems for efficient electrolysis.

- Strategies for navigating supply chain risks specifically for electrical materials and components.

- Why partnering with manufacturing specialists accelerates green hydrogen deployment.

Addressing these manufacturing realities head-on is key to unlocking the potential of green hydrogen.

Solving the BoP Reliability Crisis in Green Hydrogen Systems

While the electrolyzer stack (AWE, PEM, SOEC, AEM) performs the core chemical conversion, its successful operation relies heavily on the reliability of the Balance of Plant (BoP). Within the BoP, the electrical power conversion, distribution, monitoring, and control systems are particularly critical, alongside the mechanical components necessary to house, connect, and support this infrastructure. Failures in these areas can lead to costly downtime, reduced hydrogen output, safety incidents, or damage to the electrolyzer stacks themselves. Ensuring the integrity of components within these electrical and supporting mechanical subsystems is fundamental to project success.

The Critical Challenge: Ensuring Component Integrity in Electrical & Supporting Systems

Components within the BoP's electrical sphere and its immediate mechanical support systems face unique demands in hydrogen applications:

- High Electrical Loads: Handling significant currents and voltages requires components manufactured from high-purity conductive materials (like copper ) with precise geometries to manage electrical stress and minimise losses.

- Material Compatibility: Materials used in housings, connectors, and supports must be compatible with the operating environment, which might include humidity, temperature fluctuations, and potentially hydrogen exposure, without compromising electrical insulation or mechanical integrity.

- Precision Assembly: The correct assembly and connection of numerous electrical components (busbars, cables, connectors, sensors) are vital for safety and performance. Misalignments or improper connections can lead to high resistance points, overheating, or failures.

- Mechanical Support: Robust mechanical structures are needed to mount, align, and protect sensitive electrical equipment within the BoP skid or enclosure, often requiring custom designs and high manufacturing precision.

MSS International's Solution: Applying Manufacturing Expertise to Critical Electrical & Supporting Components

MSS International addresses these challenges by applying its core manufacturing capabilities – precision machining, pressing, assembly, and extensive copper expertise – to produce the high-quality, often bespoke, components essential for reliable BoP electrical and power distribution systems.

Precision Machining for Electrical System Components & Interfaces

Leveraging advanced CNC/VMC and Turn Mill capabilities, MSS International manufactures intricate metal components crucial for electrical system function and integration:

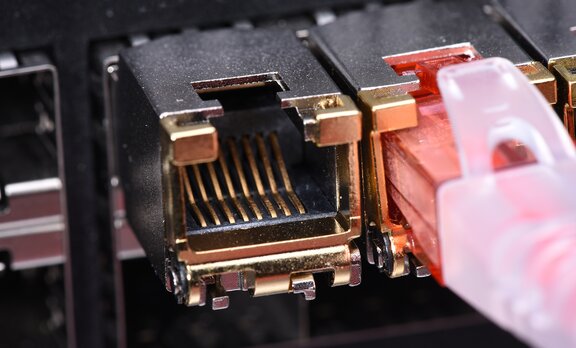

- Terminals and Connectors: Machining complex geometries in copper or other conductive alloys to ensure low-resistance, reliable electrical connections for high-current applications.

- Housings for Power Electronics & Controls: Producing precisely machined enclosures that ensure proper fit, sealing, thermal management, and protection for sensitive electronic control units or power conversion modules within the BoP.

- Structural Supports for Electrical Gear: Machining high-precision mounting brackets, frames, or interface plates required for the secure and accurate assembly of busbar systems, switchgear, or other electrical apparatus.

- Bespoke Interface Connectors: Creating custom-designed connectors or feedthroughs essential for integrating various electrical subsystems within the plant architecture.

Pressed Parts for Electrical Applications

MSS International utilises its capabilities to produce "highly complex pressed parts", often applied to electrical functions:

- Conductive Components: Pressing intricate shapes from copper or aluminium sheets for use as contacts, terminals, heat sinks, or shielding elements within electrical assemblies.

- Fabricated Electrical Parts: Creating sleeved, brazed, or plated pressed parts used in various connection or current-carrying roles within switchgear or power distribution units.

Integrated Electro-Mechanical Assemblies

Building on their component expertise and assembly capabilities, MSS International delivers pre-assembled units focused on electrical systems, simplifying integration for EPCs:

- Switchgear-Related Assemblies: Providing assemblies like "switch fuse units, earth bar, disconnectors and coil assemblies" explicitly mentioned for the switchgear industry.

- Busbar System Integration: Assembling complex busbar runs with associated connectors, insulators, and mounting structures (leveraging G Corner expertise).

- Control Panel Components: Potentially assembling specified components onto backplates or within enclosures for electrical control systems.

High-Power DC for Efficient Green Hydrogen Production: The G Corner Advantage

Scaling green hydrogen production to meet industrial demand requires deploying electrolyzer plants with capacities ranging from megawatts to gigawatts. Managing the enormous amounts of DC electrical energy needed to power these facilities efficiently and safely is a critical engineering discipline in itself. Inefficiencies in the power transmission system lead directly to higher operating costs (due to wasted energy) and reduced hydrogen output, while inadequate safety provisions create significant operational hazards.

The Challenge: Managing Kilowatts to Gigawatts of DC Power

Large-scale water electrolysis demands exceptionally high DC currents, often reaching hundreds of thousands of amperes. Transmitting this level of power from the AC-DC rectifiers to potentially hundreds of individual electrolyzer stacks presents unique challenges:

- Minimizing Voltage Drop (I²R Losses): Even small resistances in busbars and connections cause significant power losses at high currents, impacting overall plant high efficiency.

- Ensuring Uniform Current Distribution: Uneven current flow to different stacks can lead to suboptimal performance and potentially accelerated degradation of some units.

- Thermal Management: High currents generate substantial heat in conductors, requiring careful design to prevent overheating and potential failures.

- Safe Isolation for Maintenance: The ability to safely de-energize and isolate specific electrolyzer circuits or the entire DC system is essential for routine maintenance and emergency response. Standard switchgear may not be rated for these DC currents and voltages.

G Corner's Solution: Specialised Expertise in High-Current DC Systems

This specialized electrical domain is precisely where G Corner, an MSS International company, excels. Drawing on decades of experience providing high-current DC busbar systems for the demanding global electro-winning and electro-refining industries, G Corner brings unparalleled expertise directly relevant to the power distribution needs of large-scale green hydrogen plants.

Engineered Busbar Systems for Maximum Efficiency

G Corner provides fully engineered solutions, not just components. Their process includes:

- Detailed Engineering Studies: Analyzing plant layouts, rectifier configurations, electrolyzer specifications, and operating parameters to design the optimal power distribution network.

- Material Selection and Optimization: Primarily utilizing high-conductivity copper (a core MSS Products material ), fabricated through processes like stamping, bending, and machining, to minimize electrical resistance.

- Precision Manufacturing: Ensuring perfect fit and electrical contact at joints to reduce losses and prevent hot spots. The result is a custom-designed busbar system that delivers power with minimal loss, directly contributing to the high efficiency and favorable economics of the hydrogen production facility.

Robust Safety and Maintenance Solutions

Safe operation is paramount. G Corner designs and manufactures high-amperage DC disconnectors specifically for the voltage and current levels found in large electrolyzer plants (aligning with 'disconnectors' mentioned as an assembly capability). Their proven ability to supply high-amperage DC disconnectors demonstrated up to 360kAmps provides the reliable isolation capability needed for safe maintenance procedures, enhancing plant uptime and protecting personnel.

Scaling Clean Energy: Overcoming Supply Chain & Manufacturing Hurdles for Hydrogen Systems

The energy transition towards clean energy sources like green hydrogen requires not only technological advancements but also the rapid development of resilient, cost-effective, and scalable supply chains, particularly for the essential electrical materials and components. The path to establishing large scale hydrogen production globally is currently navigating significant headwinds related to materials, manufacturing capacity, infrastructure, cost pressures, and evolving policy landscapes.

The Challenge: Building Resilient Hydrogen Supply Chains for Electrical Components

Manufacturers and developers building hydrogen systems face specific supply chain and scaling challenges related to the electrical infrastructure:

- Critical Raw Material (CRM) Volatility: Beyond PGMs for PEM stacks, the sheer volume of high-purity copper required for busbars, cables, and connectors in large plants presents sourcing challenges. Price volatility and supply chain stability for electrical-grade copper and potentially aluminium are key concerns.

- Scaling Manufacturing Capacity: The industry needs reliable, high-volume production of electrical components like precision busbars, complex connectors, flexible connections, and assemblies. While global electrolyzer manufacturing capacity doubled in 2023 to 25 GW/year, with manufacturers announcing ambitious plans for 155-165 GW/year by 2030, ensuring the supporting electrical component supply chain scales effectively is equally crucial.

- Intense Cost Reduction Pressure: The drive to lower the cost of green hydrogen below competitors like grey hydrogen puts pressure on all components, including electrical systems. Finding cost-effective solutions for copper sourcing, component manufacturing (e.g., via efficient pressing or machining ), and assembly is vital.

- Policy and Regulatory Dynamics: Ensuring electrical components meet varying international standards and potentially local content requirements under policies like the US Inflation Reduction Act production tax credits adds complexity to sourcing and manufacturing strategies.

MSS International's Solution: Stability, Flexibility, and Global Reach in Electrical Materials & Components

In this dynamic environment, partnering with an established, versatile, and globally capable manufacturer focused on electrical materials and components, like MSS International, provides a crucial advantage. They offer solutions designed to mitigate these risks and support scalable growth:

Global Sourcing and Logistics Expertise for Electrical Materials

As highlighted in their brochure, MSS International excels at the global sourcing and supply of electrical materials, particularly copper. Their established network and buying power help ensure competitive pricing and reliable supply lines for the essential conductive materials needed in hydrogen power systems. They simplify the complexities of international procurement for their clients.

Flexible and Scalable Manufacturing for Electrical Components

MSS International bridges the gap between current project needs and future industrial scale for electrical parts:

- Bespoke Component Production: Utilising CNC machining to meet unique requirements for custom connectors, terminals, or interfaces in current hydrogen system designs.

- High-Volume Manufacturing: Employing processes like copper stamping, pressing, and potentially automated assembly for cost-effective production of standardised electrical components as designs mature. Their capabilities also include manufacturing flexible electrical components.

Commitment to Quality and Compliance

With ISO 9001 approval and a history serving demanding industries, MSS International operates with rigorous quality control. This ensures that electrical components meet the necessary specifications for performance, safety, and reliability in critical hydrogen applications.

Manufacturing Certainty in an Uncertain Hydrogen World

The global journey towards a sustainable future, significantly enabled by clean energy sources like green hydrogen, hinges critically on overcoming today's manufacturing and supply chain challenges, especially within the vital electrical power systems. The transition from fossil fuels requires building entirely new industrial ecosystems at unprecedented speed and scale. Delays and cost overruns in hydrogen projects often trace back to hardware reliability issues, component sourcing difficulties, or integration complexities, particularly within the electrical infrastructure.

Mitigating these risks requires strategic partnerships with manufacturers who possess not only the right technical capabilities but also the experience, stability, and specific focus required for these applications. MSS International, through the powerful combination of its deep expertise in electrical materials and component manufacturing (pressing, machining, flexibles, assembly) and G Corner's world-class specialisation in high-power DC energy systems, stands out as such a partner. They offer a proven, integrated source for the critical electrical hardware – from high-purity copper materials and precision connectors to highly engineered busbar systems and disconnectors – that forms the backbone of reliable and efficient green hydrogen production.

Choosing MSS International means choosing manufacturing certainty for the electrical core of your hydrogen project. It allows technology innovators, project developers, and EPCs to de-risk their ventures, streamline procurement of essential electrical components, ensure quality, and focus on deploying clean energy solutions faster and more effectively. In the complex landscape of the global energy transition, securing your electrical hardware supply chain with a trusted, focused partner is not just an operational advantage – it's a strategic imperative.

Stop fighting electrical component battles and start building the hydrogen future. Contact MSS International today to explore how their manufacturing expertise can secure your hardware supply chain and accelerate your contribution to a more sustainable future.

FAQ

What actually makes green hydrogen "green"?

Green hydrogen is "green" because it's produced using the electrolysis process, powered only by renewable energy sources like solar power or wind power. This makes green hydrogen without emitting carbon dioxide, unlike grey hydrogen from natural gas or blue hydrogen using carbon capture.

Why is green hydrogen production considered crucial for the energy transition?

Green hydrogen is crucial as a clean energy source to decarbonise sectors difficult to electrify directly, like heavy industry (steel, chemicals) and long haul transport. It aids the energy transition by reducing reliance on fossil fuels and cutting greenhouse gas emissions.

What are the main challenges in scaling up the production of green hydrogen?

Key challenges include the current high cost compared to grey hydrogen, the need for massive investment (sufficient funding) in manufacturing total capacity and infrastructure (like energy storage or transport for liquefied hydrogen), and ensuring reliable supply chains for components needed in large quantities.

What are the different hydrogen colours (like blue hydrogen, pink hydrogen, yellow hydrogen)?

The hydrogen colours indicate production methods and their associated emissions. Blue hydrogen uses steam methane reforming of natural gas with carbon capture. Pink hydrogen uses nuclear energy for electrolysis, while yellow hydrogen often uses grid electricity which may include photovoltaic energy but isn't exclusively from dedicated renewable sources. All aim for low carbon hydrogen.

What role does the electrolysis process play in making renewable hydrogen?

The electrolysis process is fundamental to produce green hydrogen (also called renewable hydrogen). It uses electrical energy from renewable sources to split water (H2O) water molecules into hydrogen and oxygen. Technologies like Proton Exchange Membrane (PEM) electrolyzers facilitate this process with high efficiency.

How does manufacturing expertise help lower the high cost associated with green hydrogen systems?

Manufacturing expertise lowers costs by enabling economies of scale, improving operational efficiency through standardized designs, producing components with higher efficient use of energy (like low-loss busbars), and ensuring reliability to minimise expensive downtime, making green hydrogen a more cost effective alternative.

Why is renewable integration important for producing green hydrogen effectively?

Close renewable integration ensures the electrical energy used for electrolysis is truly clean, minimising the lifecycle greenhouse gases associated with the hydrogen produced. Matching renewable energy supply (e.g., hourly) with electrolyzer operation is key for certifiable renewable hydrogen production and meeting low carbon hydrogen standards.

Back to resources