Making sustainable electrical components isn't just a nice-to-have anymore; it’s a core challenge facing our industry. It demands real action from suppliers like us, proving we’re doing more than just talking the talk. You need genuine commitment, not just greenwashing.

We know that stringent environmental regulations, rising customer expectations for eco-friendly products, and the simple need for operational efficiency are pushing the electronics industry towards more sustainable practices. At MSS International, we're committed to meeting this challenge head-on.

In this article, we want to give you a clear-eyed look at our specific approach. We'll detail the verifiable steps we take – from using significant amounts of recycled materials to implementing certified environmental management systems – to minimise our environmental impact and contribute positively.

Here’s what we’ll cover:

- Key drivers making sustainability non-negotiable for electronics manufacturing and how we respond.

- Our documented actions and results in areas like materials, energy, and waste reduction.

- How our approach benchmarks against competitors and aligns with global trends like the circular economy.

- The challenges we recognise and our strategic direction for continuous improvement in sustainable practices.

Understanding these facets provides insight into our ongoing journey towards greater sustainability in the electrical components sector.

The Non-Negotiable Shift: Why Sustainable Manufacturing Matters Now

The pressures compelling companies like ours towards more sustainable practices in the electronics industry are coming from all sides, and they’re growing. For us, manufacturing electronic components means actively addressing these drivers is fundamental to our long-term strategy and responsibilities.

Regulatory Headwinds: ESPR, WEEE, and the Compliance Tightrope

We operate in a world with increasingly strict environmental rules, especially in the EU and UK. New frameworks like the EU's Ecodesign for Sustainable Products Regulation (ESPR) are broadening the scope way beyond old directives. They're looking at durability, repairability, recycled content, and even demanding Digital Product Passports for electronic products. At the same time, rules like the WEEE Directive require us to be responsible for products at their end of life, while RoHS limits hazardous materials. The UK is reviewing its own rules too, possibly bringing in fees based on how eco-friendly products are. Staying ahead of this complex web requires us to be proactive, ensuring we (and our customers) maintain market access.

Market Demands & Risk Mitigation: Customers and Investors Raise the Bar

It’s not just regulators; our customers and partners are paying close attention too. Sustainability matters in purchasing decisions. B2B customers increasingly look into a supplier's environmental footprint and whether they practice ethical sourcing throughout the supply chain. Showing our genuine commitment builds trust. Plus, these sustainable practices actually help us manage risks – things like relying on scarce raw materials, rising energy costs, dealing with hazardous waste, and protecting our reputation. On top of that, investors increasingly use Environmental, Social, and Governance (ESG) criteria, favouring companies that take sustainability seriously.

The Efficiency Angle: Cutting Costs Through Greener Operations

We've also found that doing good for the environment often makes good business sense. Sustainable manufacturing isn't just an expense; it often leads to savings. Think about it: using energy efficient manufacturing processes cuts down utility bills. Using recycled materials reduces how much we have to spend on new raw materials. Designing ways to reduce waste and adopting circular economy ideas simply makes our operations leaner and more productive.

Our Sustainability Playbook: Actions & Evidence

Talk is cheap, so let's look at what we actually do. At MSS International, we have a structured approach to sustainable manufacturing electrical components. We've built environmental thinking into our operations and sought outside proof for our efforts across our sites in the UK, Poland, and India.

Foundation: Certifications and Governance (ISO 14001, EcoVadis)

We take our commitments seriously, which is why we have a dedicated sustainability section on our website and have earned EcoVadis Certification, validating our environmental, social, and ethical performance. Crucially, our key manufacturing sites hold internationally recognised environmental standards: our sites in Poland and India are certified to ISO 14001. This certification isn't just a piece of paper; it ensures we have a systematic way of managing our environmental responsibilities day-to-day. Alongside this, we hold ISO 9001 (Quality), IATF 16949 (Automotive Quality at MSS India), and ISO 45001 (Health & Safety) certifications – showing comprehensive control over our operations.

Material Circularity in Practice: High Recycled Content (Lead, Brass)

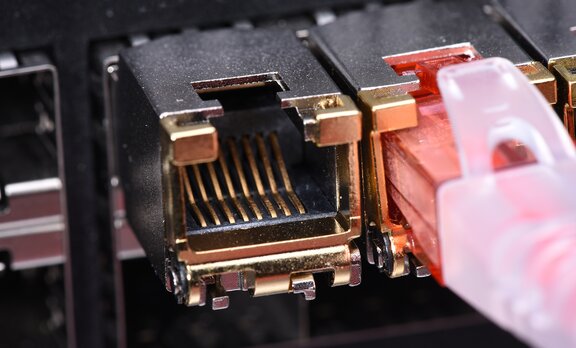

One area we're particularly proud of is our use of recycled materials. This is the circular economy in action. We demonstrate significant material circularity, utilising 90% recycled lead and 100% recycled brass in our supply chain. That drastically cuts the environmental hit from mining and processing new metals for parts like busbars and connectors. We also recycle things like the wooden packing materials from shipments, finding ways to minimise waste wherever we can.

Energy & Emissions Footprint: Solar Adoption and Carbon Sequestration

Cutting energy consumption and our carbon footprint is a major focus. We're actively switching to renewable energy sources. Right now, 25% of our group's power comes from on-site solar panels, and we have plans to increase that capacity every year. We also make sure our buildings are well-insulated and use natural light to cut down on heating, cooling, and lighting needs. And looking beyond our direct operations, we've invested in carbon sequestration by planting over 90,000 trees between 2020 and 2023, with more planned.

Operational Controls: Managing Waste, Water, and Quality

Our ISO-certified systems help us keep a tight rein on waste throughout our manufacturing and logistics processes. We focus on using resources efficiently. We're also careful about our water use, employing modern infrastructure to protect local water sources from pollution related to our activities. It’s all part of minimising our operational footprint.

Benchmarking Our Performance: Where We Stand in the Sustainable Landscape

Our Alignment with Global Trends (Circularity, Materials, Energy)

Our practices line up well with key global sustainability movements. Our high use of recycled materials puts us right in step with the circular economy push. Our solar power adoption shows we're moving in the right direction on energy efficiency and decarbonisation. And our ISO 14001 systems provide the framework for reducing waste. We know we can do more, like integrating design-for-repairability more deeply, to stay ahead of where the market and regulations are heading.

Competitive Comparison: Our Strengths and Gaps vs. Industry Peers

When we look at competitors mentioned in the research, our strengths are clear:

- Proof, Not Just Promises: Those specific 90%/100% recycled content figures are hard numbers, not vague statements.

- Verified Systems: Having ISO 14001 at our main production sites gives credible proof of environmental controls. The EcoVadis validation adds another layer of proof.

- The Whole Package: Our combined certifications across environment, quality, and safety show we manage our operations responsibly from multiple angles.

We also see areas where we aim to develop further:

- Telling Our Story Better: We can improve how we communicate our sustainability efforts, perhaps moving towards more comprehensive public reports like some industry leaders.

- Boosting Renewable Energy: We're committed to increasing our renewable energy use well beyond the current 25% solar, and setting clear targets for this is on our agenda.

- Sharpening Future Goals: We plan to define more specific, measurable targets for waste, water, and emissions reduction.

Our Readiness for Tomorrow's Rules (ESPR, Eco-Modulation)

Our high use of recycled materials puts us in a good spot if regulations like the UK's potential eco-modulated WEEE fees come into play. Our management systems help ensure compliance today and adapt for tomorrow. We're keeping a close eye on regulations like ESPR and preparing for potential new requirements around things like product durability and Digital Product Passports.

The Road Ahead: Our Challenges & Strategic Direction

Staying ahead in sustainable manufacturing requires constant effort. Like others in the electronics industry, we face ongoing challenges but also see clear opportunities.

Key Hurdles We Address: Enhancing Reporting, Targets, and Supply Chain Depth

We know we need to get better at telling our sustainability story through more comprehensive reporting. Setting clear, measurable targets is the next step in demonstrating progress. Ensuring a reliable supply of quality recycled materials, and making our entire supply chain more transparent – including ethical sourcing and avoiding harmful chemicals – are continuous priorities for our teams.

Leveraging Our Sustainability Credentials for Market Advantage

We have strong, verifiable credentials – ISO certifications, high recycled content, EcoVadis validation, our tree planting project. We need to make sure we're actively using these facts in our marketing and sales conversations. Highlighting these points can make a real difference, especially with customers in sectors like renewable energy or EVs who prioritise sustainability. Exploring cutting-edge technologies for even more energy-efficient manufacturing or new eco-friendly materials is also part of our long-term thinking.

FAQ

How does sustainable electronics manufacturing differ from traditional methods?

Sustainable electronics manufacturing, the way we approach it, means thinking about the environmental impact at every stage. Unlike older methods focused just on cost, we prioritise energy efficiency, use renewable energy, bring in recycled and eco-friendly materials, design with the product's end of life in mind (like recycling), and work hard to cut out hazardous substances and waste.

What are the main concerns regarding electronic waste (e-waste)?

Electronic waste, or e-waste, is a huge global problem we're conscious of contributing solutions to. The big worries are the massive amounts produced each year (over 62 million tonnes!), the hazardous stuff inside (like lead or mercury) getting into the environment, and losing valuable materials like copper and gold that could be recovered and reused if we embrace a more circular economy.

Can sustainable electronic components really enhance energy efficiency in electronic devices?

Yes, definitely. When we design sustainable electronic components, we often choose materials and structures that help the final electronic devices use less power. Plus, the whole push for sustainability encourages more energy-efficient manufacturing processes for parts like semiconductors, which cuts down the 'embodied energy' before the device is even turned on.

What are some eco friendly materials being explored beyond recycled materials?

Besides using more recycled materials, the industry is looking into eco friendly alternatives and even biodegradable materials. You hear about things like bio-based circuit boards using plant fibers, or even wood in some specialised electronics. We keep an eye on these developments to see what might become practical and effective for our types of components.

What role do innovative technologies like fully additive manufacturing play in sustainability?

Innovative technologies like 3D printing (additive manufacturing) have real potential for more sustainable manufacturing, and we watch these areas closely. A fully additive approach can drastically reduce material waste compared to cutting parts out of larger blocks. It also allows for lighter, more complex designs which can sometimes improve energy efficiency in the final product.

How does responsible sourcing fit into making sustainable electronics?

Responsible sourcing is crucial for truly sustainable electronics manufacturing. It's about making sure the raw materials we use are obtained ethically – avoiding conflict minerals, ensuring fair labor practices, and being transparent about where things come from. It’s about looking at the social and environmental impact way back down the supply chain.

What are some key challenges for companies aiming for greener manufacturing methods?

Like any company moving towards greener methods, we face challenges. There's often an upfront cost for new energy-efficient equipment or renewable energy systems. Securing a steady supply of quality recycled materials or finding reliable eco friendly alternatives takes effort. Sometimes production processes need rethinking, and keeping up with all the different environmental regulations takes diligence.

Our Commitment to Credibility in Sustainable Electrical Component Manufacturing

In today's world, environmental responsibility isn't just important, it's essential. At MSS International, we're committed to a credible, action-based approach to sustainable manufacturing electrical components. We base our efforts on certified management systems (like ISO 14001), real achievements in using recycled materials, and clear steps to reduce our carbon footprint, like adopting solar power and planting trees. We believe this focus on tangible evidence sets us apart.

We know the challenges ahead – evolving regulations, supply chain pressures, higher expectations – are real for everyone in the electronics industry. But we believe our strong foundation in quality, environmental management, and operational control, combined with our proven sustainable practices, puts us in a good position to meet these challenges and continue to grow responsibly. For customers looking for reliable partners who are serious about minimising environmental impact, we offer a compelling mix of manufacturing expertise and verifiable sustainability credentials. Our journey shows our commitment: integrating sustainability is key to building a resilient and competitive business for a sustainable future.

Back to resources