Essential Components and Materials

A Direct Current (DC) disconnector, also known as a disconnect switch, is a critical component in electrical systems, particularly in applications involving battery storage systems, and other DC power setups. The primary function of a DC disconnector is to ensure the safe isolation of electrical circuits, facilitating maintenance and emergency shutdowns. Understanding its composition helps appreciate its functionality and reliability.

Key Components

Contact Mechanism

The contact mechanism is at the heart of the DC disconnector. It typically consists of:

- Fixed Contacts: These are stationary contacts made of highly conductive materials like copper or silver-plated copper to ensure minimal resistance and high current-carrying capacity.

- Moving Contacts: These contacts are designed to move and engage with the fixed contacts. They are usually made of similar materials to the fixed contacts to maintain consistency in conductivity.

Actuator

The actuator is the mechanism that allows the operator to manually or automatically open and close the disconnector. It includes:

- Handle or Lever: Made of durable materials like reinforced plastic or metal, it provides the necessary leverage to operate the switch.

- Spring Mechanism: Often used to ensure a quick and decisive movement of the contacts, enhancing the disconnector's reliability and safety.

Arc Extinguishing System

When a DC circuit is interrupted, an electric arc can form. To manage and extinguish this arc, disconnectors are equipped with:

- Arc Chutes: These are made of arc-resistant materials, such as ceramics or specialized plastics, that help cool and elongate the arc, making it easier to extinguish.

- Magnetic Blowout Coils: In some designs, these coils generate a magnetic field to blow the arc into the arc chute, ensuring rapid arc suppression.

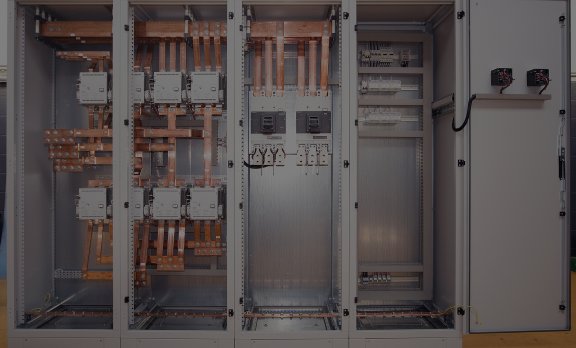

Enclosure or Frame

The enclosure and frame protect the components from environmental factors and ensures operator safety. It is typically made of:

- Thermoplastic or Fiberglass Reinforced Plastic (FRP): These materials provide excellent insulation properties and resistance to corrosion, impact, and UV radiation.

- A steel frame: Used for high strength, providing robust protection against mechanical damage and tampering. The frame allows an easy installation as maintaining all components.

Insulating Materials

To prevent unwanted electrical conduction, disconnectors use various insulating materials, such as:

- Epoxy or Resins: These are used to insulate and support the contacts and other conductive parts.

- Ceramics: Employed in high-temperature areas to ensure insulation integrity under stress.

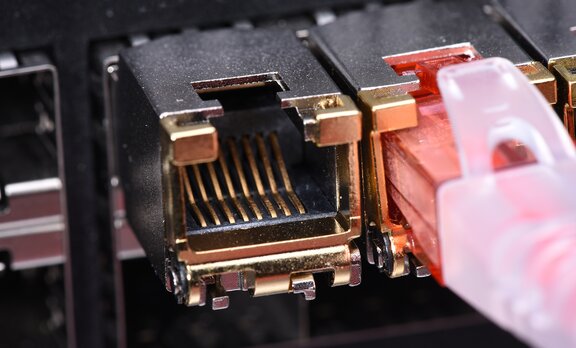

Terminals and Connectors

These components ensure secure electrical connections to the disconnector. They are usually made of:

- Copper: Usually from Copper ETP, this material offers an excellent conductivity and mechanical strength, ensuring reliable connections. MSS sources its material directly to the main market players, securing a full traceability as well as material quality, and price.

- Stainless Steel Screws and Bolts: Used for securing terminals and providing corrosion resistance thanks to nickel plating of the threads.

Conclusion

The composition of a DC disconnector combines various materials and components, each selected for its specific properties to ensure the device's overall performance and safety. By understanding these elements, one gains a comprehensive view of how DC disconnectors function and why they are indispensable in managing DC electrical systems.

Back to resources