Switchgear is the backbone of modern civilization. It’s the key to stable electrical systems in industrial facilities, commercial buildings and utility grids. By combining advanced protection devices with rugged enclosures switchgear protects critical operations in today’s power hungry world.

Switchgear is like the traffic control system for electricity. When electrical faults or overloads appear switchgear steps in to isolate affected electrical circuits and protect the rest of the network. For anyone responsible for electrical infrastructure, from small commercial sites to vast utility distribution systems, well-designed switchgear is a must.

Switchgear is the foundation of modern electrical power, it’s what makes grids around the world run with safe and efficient operation. It combines switching devices, power circuit breakers, protective devices, busbars and enclosures in one single unit. In this article we’ll cover every stage of switchgear technology – from fundamentals and major innovations to advanced manufacturing techniques. This detailed guide will help you understand how metal enclosed switchgear and other configurations form the backbone of electrical power systems worldwide.

Why Switchgear Matters

Modern civilization runs on electricity and stable electrical systems are at the heart of economic growth and technological progress. Without switchgear electrical parameters like current and voltage could become unmanageable, resulting in blackouts and equipment damage. By coordinating breakers, enclosures and switchgear devices these assemblies can handle internal arcing faults and ensure energy keeps flowing where it’s needed most.

What Is Switchgear?

Switchgear is a broad term describing an assembly of enclosures, breakers and switching devices to manage electrical circuits. It’s the protective backbone of power systems ensuring safe isolation, overload protection and easy maintenance routines.

Definition and Purpose

Switchgear is a switchgear assembly of switchgear enclosures, breakers and fuses to:

- Control current flow across electrical circuits

- Protect critical assets from overloads and short-circuits

- Make maintenance possible by isolating equipment without shutting down the entire electrical network

From air insulated switchgear (AIS) to gas insulated switchgear (GIS) the underlying purpose remains the same: safe and efficient operation of electrical power installations.

Switchgear in Electrical Systems

In electrical and electronics engineers’ terms switchgear is critical for stability in power systems. Whether it’s in a local substation feeding industrial buildings or a national grid with many feeder circuits, switchgear devices must respond fast to any abnormal situation. A well designed switchgear installation ensures system reliability and has reliable control panels so operators can avoid extended outages.

Basic Functions and Features

Switchgear excels at:

- Fault Isolation – When electrical faults occur breakers trip to limit damage.

- Load Management – By opening and closing switching devices operators can redirect electricity to meet demand.

- System Protection – Advanced relay technology monitors electrical parameters (voltage, current, frequency) and sends trip commands as needed.

Whatever the maximum voltage level or the switchgear line up the core purpose remains the same: keep people and equipment safe and maximize uptime.

Core Components of Modern Switchgear

Switchgear combines several critical elements – circuit breakers, busbars, relays and more – to ensure power flows where it’s needed without compromising safety or reliability.

Power Circuit Breakers

Power circuit breakers are at the heart of every switchgear line up. When excessive current or a short-circuit is detected these devices open the circuit in milliseconds. Breakers vary:

- DC power circuit breakers – Found in renewable energy storage and certain industrial DC systems

- Molded Case Circuit Breakers (MCCBs) – Handle medium level fault currents, suitable for commercial applications

- Low voltage circuit breakers – Common in smaller panels up to 1 kV

Each breaker type must handle high fault energy to minimize impact on the overall power supply.

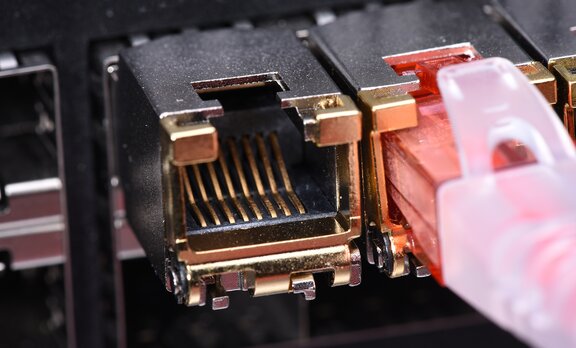

Switching Devices and Load Break Switches

Switchgear systems also employ simpler switching hardware like load break switches. Although they don’t have the full interrupting capacity of circuit breakers these switches safely connect or disconnect a circuit under normal load conditions. Together with circuit breaker pulls and other operating mechanisms, electrical disconnect switches make equipment isolation and safe and efficient operation possible.

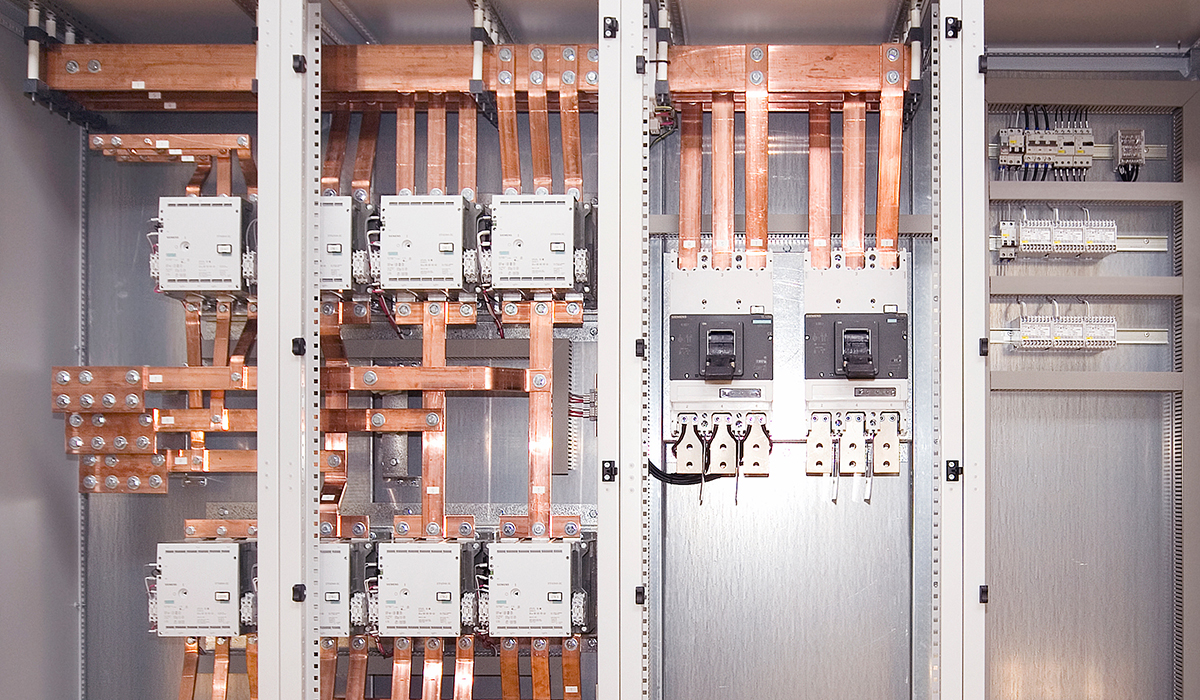

Busbars and Conductors

At the heart of any switchgear line up are power conductors called busbars. These bars, often made of copper or aluminum, carry current between switchgear components. Modern designs feature:

- Laminated bus plates to reduce resistance

- Flexible connectors to dampen vibration

- Metal enclosure systems to shield them from contaminants

MSS International produces high precision busbars for complex electrical switchgear applications.

Protective Relays and Sensors

Protective relays monitor electrical parameters – current, voltage and more. If they detect an anomaly they send a trip signal to the breaker to isolate electrical equipment. With sensors they offer fine grain control of power flow and prevent major faults.

Switchgear by Voltage

Voltage level determines design, complexity and fault handling capabilities of switchgear. Each category – low, medium and high voltage – serves a specific purpose in modern power distribution.

Low Voltage Switchgear

Low voltage (up to 1kV) usually contains:

- Molded case circuit breakers

- Miniature circuit breakers (MCBs)

- Simple relays and busbars

These power small commercial and residential loads. They’re compact, easy to maintain and critical for everyday operation.

Medium Voltage Switchgear

Operating between 1kV to 36kV, medium voltage circuit breakers protect and manage industrial facilities, large commercial sites and local distribution grids. Fault energy is higher at these voltages so more robust technologies come into play:

- Vacuum circuit breaker modules to extinguish arcs within sealed vacuum bottles

- Arc resistant switchgear designs to confine arc energy and protect people

- Metal clad arrangements that segment busbars, breakers and cables

High Voltage Switchgear

High voltage switchgear handles voltages above 36kV where the stakes are much higher. Gas insulated switchgear (GIS) is common here due to its compact size and high reliability. In older or specialized applications you’ll still find oil insulated switchgear or classic oil circuit breaker, but modern systems are trending towards SF6 free or vacuum.

Switchgear Enclosures and Configurations

Different enclosures ensure live parts are contained, reducing accidents and environmental contamination. Each configuration meets specific application requirements from compact urban substations to large industrial facilities.

Metal Enclosed Switchgear

A metal enclosure is the most common housing for switchgear. All live parts are fully enclosed, improving safety and reducing contamination. This can be placed in accessible areas without exposing operators to live parts. By confining internal arcing faults metal enclosed switchgear reduces risk to people and nearby equipment.

Metal Clad Switchgear

Metal clad switchgear is a subcategory of metal enclosed switchgear. It has compartmentalization: each section (busbar, breaker, cable termination) is isolated. This design:

- Allows certain sections to be de-energized while others are live

- Supports safer maintenance practices

- Minimizes arc faults from propagating across sections

Switchgear and Switchboards

Although often used interchangeably switchgear and switchboards have a slight difference in scope. Switchboards usually consolidate low voltage circuit breakers or distribution breakers while switchgear covers a wider range of voltages and has more advanced protective devices. Both however have the same objective: to control power flow reliably.

MSS International is a reliable partner for the design, production, and delivery of advanced switchgear and components for modern power systems. Contact us today to speak to an expert who can help you through the procurement process.

Switchgear Innovations

The switchgear industry is rapidly evolving with new materials, automation and digital technologies shaping the future of power distribution. These innovations reduce operating costs, improve safety and simplify grid management.

Advanced Copper Busbar Systems

Recent developments involve laminated copper plates with minimal joints and reduced energy loss. Some designs have flexible joints for smoother current flow and to absorb mechanical stresses. As a result internal temperatures drop and it can operate more reliably at higher loads. Lamination reduces inductive reactance and increases system efficiency.

Vacuum Insulated Switchgear

Vacuum insulated switchgear has sealed chambers to extinguish arcs without using oil or SF6 gas. Advantages are:

- Less Maintenance – Vacuum interrupters remain stable after many operations

- Cleaner Footprint – No hazardous substances to dispose of

- Compact Size – Tightly arranged components fit in indoor switchgear cabinets

This has become a standard in medium voltage applications offering a great balance of performance and environmental responsibility.

Gas Insulated Switchgear (GIS) and SF6 Alternatives

Gas insulated switchgear houses conductors and breakers in a sealed tank. The insulating gas (historically SF6) provides excellent dielectric strength and enables smaller footprint:

- Urban Substations – GIS fits where space is limited

- Harsh Environments – Environmental sealing prevents dust or moisture ingress

Eco friendly gases are emerging to replace SF6 to meet global sustainability requirements while preserving GIS benefits.

Digital Monitoring and AI Integration

Modern switchgear is getting connected. Smart relays and sensors gather real time data on load levels, contact wear and ambient conditions. AI algorithms can then predict potential issues before they become a problem and reduce downtime. Remote operation becomes possible, engineers can manage switchgear devices without physical intervention, very useful for large or remote sites.

More Breakthroughs and Trends

Beyond the basics, new approaches to breakers, arc containment and hybrid designs are transforming power distribution in established and emerging markets.

Solid State Circuit Breakers

Solid state breakers use semiconductors instead of mechanical contacts:

- Ultra Fast Interruption – React to overloads or short circuits in microseconds

- Minimal Arcing – No physical gap to ionize

- Simplified Maintenance – Fewer moving parts to wear out

Although still an emerging technology, solid state breakers promise a new era of fast and reliable protection for critical loads.

Arc Resistant Switchgear

Arc resistant switchgear focuses on containing the explosive force and heat of an internal arc. Innovations include venting structures that channel gases away from operators, reinforced metal enclosures and intelligent trip systems that limit arcing duration. These solutions greatly enhance worker safety especially in industrial facilities with high fault rates.

Hybrid Switchgear

In some distribution systems air insulated switchgear merges with gas or vacuum compartments. This hybrid approach balances cost and performance, upgrading older equipment to modern standards without a full rebuild. Utilities also get smaller footprints and lower maintenance, bridging the gap between fully air based and fully gas based configurations.

The Manufacturing Process

Manufacturing switchgear components requires precision and expertise. MSS International uses advanced tooling, rigorous testing and global logistics to deliver high quality products for various power applications.

Raw Materials and Forging

MSS International starts with top grade raw metals, copper:

- Copper Forging – Achieves uniform grain structure, critical for high current connections

- Precision Tooling – Allows forging of complex shapes to support unique designs

By forging metals MSS International ensures switchgear components that can withstand mechanical stresses in industrial buildings and utility infrastructure.

Machining and Assembly

After forging CNC machining refines parts to exact dimensions. For example shaping a vacuum circuit breaker housing or busbar segment might require multiple milling, turning and drilling operations:

- Tight Tolerances – Reduces hotspots and ensures contact surfaces are reliable

- Modular Sub-Assemblies – Combines busbars, breakers and interlocks into partial builds to speed up switchgear installation

This approach gives a consistent switchgear assembly whether for a big substation or a specialized site with tight specs.

Finishing and Coating

Surface treatments extend part life and conductivity:

- Electroplating – Improves corrosion resistance and reduces contact resistance

- Powder Coating – Protects steel frames in harsh environments

- Partial Plating – Applies conductive coatings where needed to improve efficiency

By targeting critical surfaces MSS International minimizes material waste and maximizes performance.

Testing and Quality Control

Quality is non negotiable in any switchgear line up:

- Electrical Tests – Simulates electrical faults at various voltages and currents to confirm safe interruption

- Mechanical Checks – Verifies alignment of load break switches, breakers and busbars

- Standards Compliance – Meets national electrical code, national electrical manufacturers association guidelines and other relevant bodies like national fire protection association

This thorough vetting makes MSS International your go to partner for reliable high performance switchgear. To verify this, you can view our safety certificates and standards.

MSS International: A Bespoke Switchgear Specialist

MSS International’s approach to design, manufacturing and global support sets them apart in an industry that demands innovation and quality.

Global Presence and Capabilities

MSS International has manufacturing plants in multiple regions, fast delivery and local support. Their flexible global supply chains handle various metals, copper to aluminum. This breadth allows them to meet specialized orders at scale – like producing dc power circuit breakers for renewable projects or advanced switchgear enclosures for high voltage substations.

Custom Assemblies and Large Scale Production

We can produce over a million parts a year but also thrive on custom projects. Whether a client needs one off parts for a pilot program or a full switchgear line up for massive industrial facilities, MSS International can deliver without compromising on quality. This flexibility is what sets us apart in a market that demands customization.

Copper and Recyclability Focus

Copper is essential in electrical components because of its conductivity and recyclability. MSS International’s forging expertise uses copper’s properties while minimising waste. Recycled copper can be reused multiple times without performance loss, so the resulting modern switchgear solutions are eco friendly and cost effective.

Sustainability and Eco Friendly Approaches

Environmental responsibility is top of mind for power system stakeholders. MSS International addresses this through cleaner insulating media, responsible sourcing and intelligent design.

SF₆ Free Solutions

With SF₆ recognised as a potent greenhouse gas, manufacturers are developing new insulating media for gas insulated switchgear. MSS International stays ahead of the curve by exploring low GWP alternatives that match SF₆’s dielectric properties while slashing environmental impact.

Green Manufacturing Practices

Beyond insulating gases MSS International uses energy efficient production lines, reuses scrap metal and follows eco conscious guidelines during forging and plating. These measures reduce the green footprint, in line with global trends in electrical infrastructure development.

Lifecycle Design and Modular Upgrades

Forward thinking design allows for quick replacement of worn parts, from case circuit breakers to contact assemblies. Modular frameworks also reduce downtime during expansions or technology updates. Design for disassembly and component reuse minimises environmental impact while preserving system reliability.

Real World Applications

Switchgear is used across multiple sectors, from energy to commerce. Its reliability and adaptability makes it the linchpin in maintaining safe and efficient power distribution.

Industrial Facilities

In large plants processing metals, chemicals or machinery arc resistant switchgear is often needed. Medium voltage circuit breakers protect motors and transformers from damage. By including advanced relays and robust busbars facility managers can minimise production downtime due to fault events.

Commercial Buildings

Malls, hospitals and office complexes rely on switchgear and switchboards to feed multiple feeder circuits and keep power stable. Using molded case circuit breakers at each distribution point ensures any localised fault won’t affect the whole building, keeping services uninterrupted.

Renewable Energy Projects

DC power circuit breakers are used in solar farms, battery storage or hybrid systems. In many cases a vacuum circuit breaker or gas insulated switchgear can handle the fluctuating loads of renewables. Modern designs may also incorporate sensors for real time data sharing with energy management systems.

Power Utilities and Transmission

At the grid level oil circuit breaker technology is being replaced by vacuum or SF₆ free solutions. Large air insulated switchgear or gas insulated switchgear maintains high reliability in transmission lines. Fault detection and fast clearing time is critical to safeguard entire regions from blackouts.

Key Standards and Regulations

Compliance to established codes and guidelines ensures that switchgear is both safe and fit for purpose. These standards govern design, manufacturing and installation practices worldwide.

National Electrical Code (NEC)

Developed by the NFPA the national electrical code governs safe electrical design and installation in the US. It covers grounding, breaker sizing and more. Any switchgear installation must conform to these rules to ensure reliability and safety.

National Electrical Manufacturers Association (NEMA)

The national electrical manufacturers association sets performance standards for many electrical products including switchgear enclosures, breakers and drives. By adhering to NEMA ratings equipment manufacturers guarantee product interoperability and consistent quality across the industry.

International Electrotechnical Commission (IEC)

While NEC and NEMA apply in North America, IEC provides global standards. OEMs looking to go global design their switchgear devices to meet IEC standards so they can be accepted across multiple regions and distribution networks.

National Fire Protection Association (NFPA)

NFPA codes address fire safety which is critical in areas with high arc energy or combustible materials. The articles in these standards cover everything from switchgear room ventilation to protective gear for electrical workers, so switchgear can operate safely and efficiently even in the most challenging conditions.

Future Outlook

The pace of change in the electrical industry is accelerating, driven by innovation in materials, automation and digital systems. Future switchgear will reflect this with more intelligence and less environmental impact.

Next Generation Switching Devices

Future switchgear will have faster response time, higher fault withstand capability and integrated intelligence. Solid state circuit breakers may become mainstream enabling microsecond level current interruption that limits damage during severe faults.

Automation and Robotics in Manufacturing

More and more manufacturers are using robotic arms for tasks like busbar bending, precision drilling and assembly. MSS International is investing in automation to reduce lead times and ensure build quality especially for large or complex orders.

Digital Twins and Virtual Testing

Engineers can now create digital models of modern switchgear, simulate performance under different conditions – extreme loads, short circuits, temperature spikes. These “digital twins” help design refinement before production, ultimately reducing reliability and lower lifecycle cost.

FAQs

What is switchgear used for?

Switchgear is used to manage, protect and isolate electrical circuits in electrical power systems. It ensures safe operation by detecting and interrupting electrical faults, routing power to different loads and enabling maintenance without shutting down the entire electrical network.

What is the difference between transformer and switchgear?

Transformer changes voltage levels to support power flow while switchgear houses switching devices, fuses and breakers to protect and control those circuits. Transformer adjusts voltages between generation, transmission and consumption points; switchgear isolates faults, manages loads and keeps the grid safe and stable.

What are the three types of switchgear?

There are three main types – low voltage switchgear (up to 1kV), medium voltage switchgear (1kV-36kV) and high voltage switchgear (above 36kV). Each type uses specific voltage circuit breakers and designs tailored to the fault levels and safety requirements of their operating range.

What is the difference between switchgear and circuit breaker?

Circuit breaker is a protective device that interrupts current during a fault while switchgear is the entire assembly containing breakers, busbars, switchgear enclosures and controls. Switchgear provides the framework for safe power distribution and circuit breaker is one component within that framework.

What is an example of switchgear?

A typical example is a metal enclosed switchgear setup in a commercial building. It has molded case circuit breakers, busbars and protective relays inside a metal enclosure. This assembly isolates faults, manages loads and maintains power reliability across multiple floors or departments.

Conclusion

Switchgear is at the core of every electrical infrastructure, from small town grids to national distribution networks. Vacuum insulated switchgear, gas insulated switchgear, digital monitoring and eco-friendly designs keep up with the growing energy demand. MSS International is ahead of the curve, producing high precision copper parts, introducing rugged designs and custom assemblies to meet the tough demands of modern power networks.

Switchgear not only ensures safety and efficiency but also is the foundation for infrastructure growth and technological advancements. By adopting new materials, exploring new standards and automating manufacturing, manufacturers like MSS International keep pushing the boundaries of performance and sustainability.

If you need efficient and reliable solutions for your next switchgear installation, consider working with MSS International. Our global presence, state of the art manufacturing capabilities and innovation focus ensures you get modern switchgear that lasts. From forging busbars to final quality checks, MSS International delivers on performance, safety and sustainability. We can help you power your network for years to come.

Back to resources