In today’s industrial world, bespoke product designs and on demand solutions have never been more in demand. Companies across the power, data and automation sectors require components that meet their technical specs, budget constraints and sustainability goals. As a bespoke manufacturing company (often referred to as a BMC) MSS International leads the way by providing highly specialist assemblies to clients in critical industries. This in house design under one roof means every project from concept to delivery fits seamlessly into each client’s infrastructure.

Here are the key points we’ll cover in this article:

- Why custom manufacturing is key to a more sustainable future in energy systems and data management.

- How bespoke solutions mean less material waste and align to a sustainable future vision.

- What benefits come from advanced production methods, inventory management and freight solutions.

- Which industries benefit most from bespoke assemblies and how can they scale up to meet their complex challenges.

In the sections below we look at how bespoke assemblies revolutionise manufacturing for critical power applications, the benefits of this custom approach and the future of specialisation as the world moves towards a more sustainable future.

The Power Industry: A Prime Customer for Bespoke Assemblies

The power industry – generation, transmission, distribution and storage – requires components that are efficient, stable and cost effective. Whether delivering power to a remote industrial site or supporting large data centre power demands, a bespoke manufacturing company can tailor each assembly to the specific engineering challenges. MSS International’s approach aligns to the increasing focus on business continuity, machine performance and a sustainable future for energy infrastructure worldwide.

To understand how we could help your business, take a look at our Manufacturing Capabilities page. We offer custom assemblies and sub-assemblies, hot forging, CNC machining, and more.

Electric Transmission and Distribution

One of the key areas where bespoke assemblies excel is electric transmission and distribution. Unlike off the shelf components, custom solutions can be designed to meet precise voltage, thermal and mechanical load requirements:

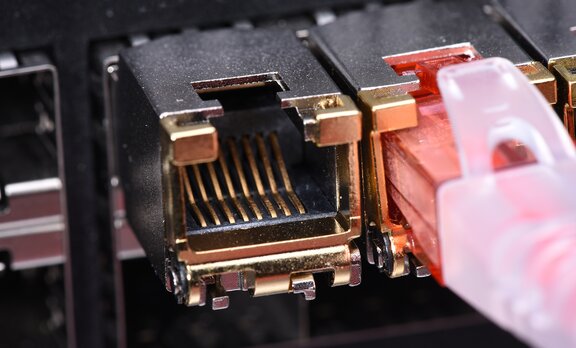

- Custom Connectors and Components – MSS International develops specialist copper fittings, busbars and joint assemblies that handle high electrical loads efficiently, lower transmission losses and save money in the long run.

- Tailored Distribution Solutions – By considering environmental factors (heat, humidity, dust) components are more reliable under stress so operators can optimise line capacity and reduce the risk of outages.

- Reduced Inventory Burden – Since each assembly is manufactured to order, utilities and OEMs can reduce excess stock, cut costs associated with storage and obsolescence and meet the exact requirements of their clients.

This in-house design under one roof means each bespoke product aligns perfectly to local regulations, site constraints and performance targets from small substations to large scale grid expansion.

Power Storage Solutions

As the world moves towards a more sustainable future energy storage systems (ESS) like batteries, supercapacitors and flywheel based systems become more critical. MSS International’s custom manufacturing capabilities allow for:

- Bespoke Battery Cell Components – Precise copper busbars and conductive plates to maximise energy transfer with minimal voltage drop.

- Sustainable Future Designs – Materials and coatings selected for durability reduce the need for replacement over time, fewer resources wasted.

- On-Demand Production – When new storage projects come up or existing systems scale, assemblies can be delivered quickly without large upfront inventory investments or guesswork, so businesses can stay agile.

These specialist assemblies not only improve the efficiency of ESS installations but also deliver better lifecycle performance – essential for companies aiming for net zero carbon and more efficient power storage solutions.

We offer a range of products for the energy storage market. Every product starts with your specific needs and project goals. Take a look at our Energy Storage solutions and then get in touch. Our team can guide you through the process of achieving custom manufacturing for your parts.

High Current DC Power Systems

High current DC power systems present unique engineering challenges due to high temperatures, high current levels and potential EMI issues. By using bespoke manufacturing:

- Custom-Designed DC Busbar Systems – MSS International’s design and forging processes produce busbars that can handle massive current loads with minimal resistive losses, so clients in heavy industry, rail networks or large data centres can benefit.

- Enhanced Efficiency and Performance – Streamlined metal flows and optimised shapes reduce energy dissipation. This direct correlation with cost and savings – through reduced power losses – can add up to substantial bottom line benefits.

- Scalable Configurations – As businesses grow, expansions or upgrades are simplified by modular, custom fit DC systems that can be swapped or added without disassembling the entire infrastructure.

These bespoke approaches align to business needs: to be successful through reliability, adaptability and cost management.

Benefits of Bespoke Assemblies in Manufacturing

While off the shelf components may be sufficient in some cases, bespoke assemblies deliver an edge where precision, reliability and performance matter. MSS International’s integrated model under one roof combines design, forging, machining, finishing and testing, yields multiple benefits:

Increased Precision and Quality Control

In bespoke manufacturing excellence is achieved through quality checks and advanced machinery:

- Reduced Human Error – Automated processes and digital tooling allow the team to maintain consistent tolerances so each piece fits perfectly in its end application.

- Improved Accuracy – Sophisticated forging hammers, CNC machines and real time monitoring systems result in dimensionally stable parts even at high volume production.

- Data-Driven Inspection – By analysing metrics such as temperature, pressure and metal flow MSS International can detect anomalies early, track them and correct issues before large batches are produced.

This saves clients the downtime, replacement costs and frustration that comes with subpar components. Over time businesses save money and uphold brand reputation for reliability.

Cost-Effectiveness and Waste Reduction

Although “custom” can sound expensive, properly executed bespoke manufacturing is often more economical:

- Lower Unit Costs – When specialized parts are made to spec there’s less risk of rework or mismatched components. Over time this precision pays off in stable operational performance and minimal scrap.

- Minimised Material Wastage – Typically forging processes designed around a final geometry produce less offcut material. Combined with real time data on each batch bmc operations can keep resource use to a minimum.

- Lifecycle Savings – High quality assemblies last longer, reduced maintenance intervals and replacement frequency – another factor that adds to total cost of ownership (TCO).

Plus sales and customer satisfaction grows when businesses can promote the reliability and longevity of the bespoke product they’re supplying.

Increased Production Efficiency

Meeting tight deadlines or coping with seasonal demand surges becomes more manageable when manufacturing is streamlined from start to finish:

- Streamlined Manufacturing Process – Having everything under one roof means fewer logistical hurdles, fewer external dependencies and less chance of confusion among subcontractors.

- Faster Turnaround Times – Changing tools, fixtures or design specs is quick when the whole team is on site and has direct access to the forging floor.

- Support for Scalability – As businesses grow or pivot production lines can adapt quickly. From small pilot runs to full volume production the same flexible line can be retooled to meet new specs and ensure continuous growth for MSS International and its clients.

By combining these elements bespoke manufacturing creates a positive cycle: better efficiency means better cost metrics, stronger sales and overall higher customer success.

Industry Specific Requirements

Every industry has its own set of challenges and requirements – from high temperature environments to strict regulations. Bespoke assemblies excel because they can be tailored to specific demands, so are essential for businesses that want to reduce risk, improve performance and stand out in a competitive market.

Addressing Customer Requirements

No two customers have the same setup or constraints. By working with a bespoke manufacturer like MSS International:

- Flexibility in Design – Clients specify key parameters such as shape, size, conductivity and mechanical strength. The result is a bespoke product that fits seamlessly into an existing or new system.

- Complex Component Creation – From forging intricate geometries to advanced finishing, custom assemblies can accommodate even the most specialist use cases.

- Industry-Specific Solutions – Certain industries – automotive, aerospace, telecommunications – may require specialist copper alloys or finishing techniques to meet safety or performance standards.

Since these products are made to order inventory is optimised and end users can reduce overhead tied to storing surplus parts. Plus this is particularly beneficial when dealing with mission critical applications where reliability is paramount.

Adapting to Technology

Innovation is constant in industries like power and data – what worked 5 years ago may be outdated. Bespoke processes thrive on:

- Cutting-Edge Manufacturing Techniques – Techniques such as friction welding, advanced forging hammers or multi axis CNC finishing can address emerging design complexities.

- Compliance with Evolving Standards – As governments and industry guidelines move towards a sustainable future custom assembly makers can update designs to follow new regulations quickly.

- IoT and Smart Features – With advanced production lines and real time data tracking MSS International can add sensors or other features into the metal components if required, future proofing the end application.

All this allows clients to stay ahead of competition and adapt their industrial processes without overhauling entire systems – an essential advantage in fast moving markets.

MSS International’s Approach to Bespoke Manufacturing

A key differentiator at MSS International is the bmc framework – everything from design to finish is under one roof. Plus the company’s focus on a sustainable future, process optimisation and building client relationships, this structure delivers consistent high quality output.

Global Reach and Local Expertise

MSS International uses an international footprint and local knowledge to serve multiple markets:

- Strategic Locations – Facilities near industrial hotspots reduce freight costs, lead times and carbon footprint of shipping.

- Local Compliance – Different countries have different certifications or regulatory requirements. With a multicultural team and wide experience MSS International can adapt assemblies quickly.

- Business Continuity – Redundancies in the supply chain and local backups give clients peace of mind when global market or policy changes happen suddenly.

Such global reach plus local agility encourages long term relationships – critical in industries where major decisions are not taken lightly and trust is key.

End-to-End Service

Unlike traditional service models where design and production are separate MSS International’s integration brings synergy at every stage:

- Conceptualisation – The company’s design team works with clients to clarify operational demands, mechanical specs and cost considerations.

- Advanced Production – Once the design is finalised forging and finishing is done under one operational umbrella, eliminating miscommunication and production delays.

- Quality Assurance – Multiple verification checkpoints and real time data logging ensures consistency across batches.

- Delivery and Support – Assemblies are delivered quickly with after sales support to ensure each part meets or exceeds performance metrics.

By eliminating handovers between external suppliers MSS International is accountable at every stage – reducing client anxiety and providing a single point of contact.

Future of Bespoke Assemblies in the Power Industry

From new materials to AI driven design optimisation the power industry is on the cusp of a revolution. Bespoke manufacturing is ready to address new challenges and new opportunities so manufacturers, utilities and data centre operators can adapt seamlessly.

Emerging Trends and Technologies

Several themes are shaping the future of custom made copper components in energy systems:

- Smart Manufacturing – Digital twins, 3D modelling and real time sensor feedback enables predictive maintenance and efficient resource usage. This increases reliability and reduces waste, getting us closer to a sustainable future.

- Green Materials – Research into new copper alloys or coatings can deliver higher performance with lower environmental impact, aligns with corporate commitments to a more sustainable future.

- Modularisation – Large equipment such as battery storage units or substation components is moving towards modular designs. Bespoke assemblies thrive here with easily swappable modules that can be adapted to expansions or system changes.

- AI Optimisation – Over time, AI-based tools can refine forging parameters, reduce scrap and maintain quality, build more trust with clients and industry stakeholders.

MSS International’s vision for Innovation

Looking ahead MSS International has a leadership perspective that marries technical innovation with practical solutions:

- Collaborative R&D – By working with research institutions the company is exploring new forging methods and refined process controls.

- Employee Development – From shop floor operators to the CEO, the whole team is excited about continuous improvement, driving an ever present culture of craftsmanship.

- Global Partnerships – As the business grows new brands and potential co-developers emerge, bringing fresh ideas and forging styles to test in real world scenarios.

- Transparent Communication – Whether it’s project timelines, cost breakdowns or sustainability metrics MSS International puts transparency first. This builds deeper relationships and credibility on the world stage.

These initiatives mean MSS International – and its clients – will be competitive in the fast changing power world, growing markets and increasing environmental demands.

Conclusion

With the power sector’s rapid changes, growing data centre requirements and the global call for sustainability bespoke assemblies deliver solutions that combine efficiency, reliability and cost optimisation. MSS International’s in-house design process under one roof is a proven way to tackle the many challenges faced by modern industries from electric transmission and power storage to high current DC applications.

By focusing on precision, cost, minimal inventory and robust quality checks MSS International delivers what customers need to succeed in competitive markets. The company’s wide perspective, global reach, advanced forging and R&D is ready for a world where technology, sustainability and market demands converge.

Whether you’re a utility manager looking to reduce failures, a data centre operator optimising internal machine performance or an industrial giant seeking copper solutions, MSS International is here to help. By combining custom designs with strategic freight logistics, data driven forging controls and a team culture of excellence the company delivers top tier bespoke product assemblies. As the world moves towards sustainability, on demand production and infrastructure expansion bespoke manufacturing is more relevant than ever. MSS International’s commitment to quality, the environment and continuous improvement is for clients who want to imagine, see and shape the industrial future – today.

Back to resources